Features

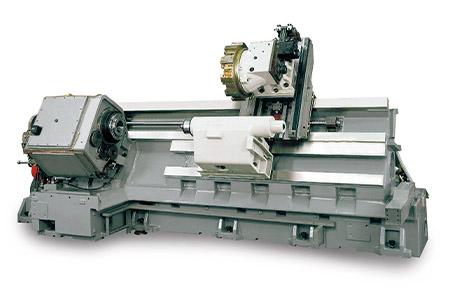

Vturn-40 & Vtuen-45 Turning Center

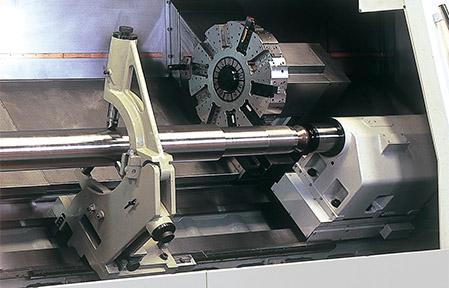

Heavy cutting lathe with spindle nose A2-11 for turning length from 1250mm to 4250mm.

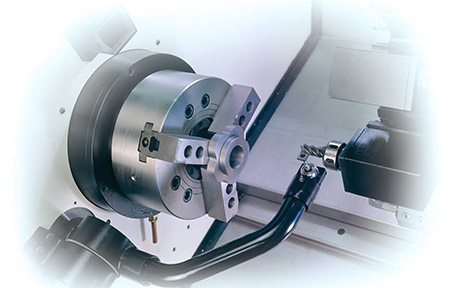

- Spindle bore A2-11 with hydraulic 15" chuck

- One piece 45 slant bed

- Large swing diameter 780 mm

- Turning length 1250 / 2200 / 3250 / 4250 mm

- 2-step gearbox included

- C-axis and Y-axis available

- Available with Large Spindle Bore (LSB)

160 mm / 205 mm (XSB)

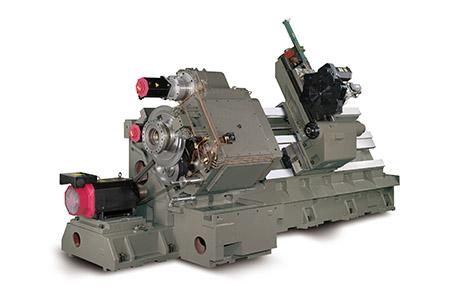

Vturn-46 Turning Center

Built-in 4-step gearbox for powerful heavy cutting!

- Genuine 60° slant bed for minimum distance form Z-axis ball screw to the tool tip so as to reduce the chip built-up.

- Built-in 4-step gearbox inside the headstock further enhances the cutting torque 536.4kg-m at low spindle 67rpm.

- Spindle nose A2-11 with hydraulic 15" chuck is offered as standard and available with 18"/ 21"/ 24 chucks.

- Z-axis ballscrew diameter 50mm.

- Maximum turning length 1650mm.

- Available with C-axis spindle and live tooling by Victor's own VDI turret.

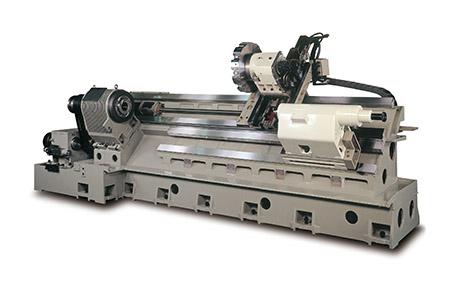

Vturn-40 & Vtuen-45 C Axis & Y Axis Application

- 2 step gearbox upgrade (by GTP)

- Victor's own servo turret for quick indexing:

1.0 sec (adj.), 1.2 sec. (opposite) - Milling turret with VDI-50 disk or BMT-75 disk (12 station live tools)

- Milling power 7kW / 3000rpm

Vturn-46 C-axis VDI turret with live tooling (CV option.)

- Live tooling is provided through the use of VDI turret which not only provides an international tooling system but also allows for quick and simple tool mounting.

- Cf-axis design with angular encoder is included as standard to assure high indexing accuracy.

- Coupling specification DIN-5480.

- Milling power 7kW/3000rpm.

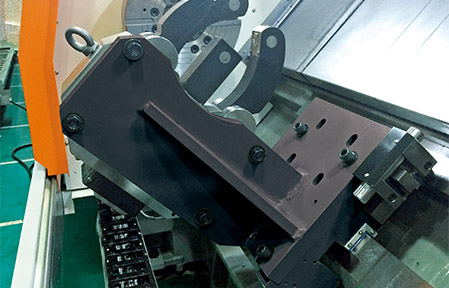

Victor's Own Turret

- Wide span turret carriage upgrades structures stiffness.

- Milling turret (servo driven) available with VDI 50 interface for quick tool change or BMT 75 interface for high rigidity.

Tailstock MT5

- Twin cylinder clamping

- Built in bearings for fixed center

- Two along by turret

- Programmable by M code

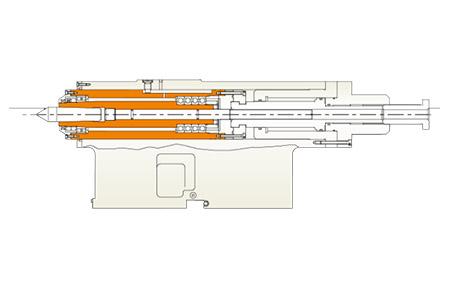

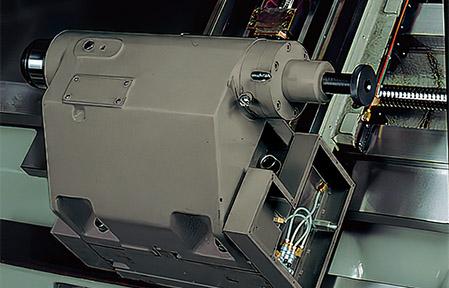

Vturn-40 & Vtuen-45 Opt. Built in Spindle 45kW (30 min.)

- Bar capacity 106mm (spindle bore: 116mm)

- Spindle speed 2500 rpm

- Spindle output 1423 Nm (S3 15 min.)

- Good for contour milling

Programmable Tailstock

- Mounted on slideways for maximum clamping stability.

- Hydraulic clamping to bed with variable hydraulic pressure to tailstock quill.

- Progrannable tailstock (std.)

Oil Skimmer (Opt. for VT-46)

Coolant Flush (Std.)

Manual Steady Rest

- Manual steady rest (std. for Vturn-40(45)/220, 325, 425)

- Clamping range: 280 ~ 400mm (or 150 ~ 300mm)

Tool Presetter (Opt.)

Hydraulic Steady Rest (Opt.)

Accessories

Standard :

- Power chuck with soft jaws

- Programmable tailstock

- Chip conveyor with cart

- Automatic forced lubrication

- Fully enclosed splash guarding

- Tool holders (excl. VDI / BMT turret system)

- Fanuc 0i-TF Plus (10.4") control

- 3 step warning light

- Air conditioner for electrical cabinet

- Fanuc e-books (CD)

Optional :

- Kitagawa chuck

- Hard jaws

- Tailstock center

- Manual tool presenter

- Automatic tool presenter

- High pressure coolants

- Auto door

- Air blow system

- Oil-mist remover

- Oil skimmer (std. on Vturn-40,45)

- Steady rest (Manual or hydraulic)

- C-axis with live tooling

- High/low chucking pressure Fanuc manuals