Taiwan excels with an integrated production process ….

Victor Taichung excels with integration of production process, ensuring high self-sufficiency, efficiency, precision, and superior manufacturing quality.

01Custom Solutions

R&D capabilities enable us to tailor smart machinery and automation solutions, empowering our customers and serving as their solid support.

Our Customer Value Application Center features a comprehensive technical team dedicated to enhance equipment efficiency and deliver maximum added value to our customers.

Flexibly meet customized demands.

1. Improve efficiency through demand assessment and automation.

2. Offer solutions for production line planning and process analysis.

3. Provide trial runs and comprehensive testing with technical support.

4. Implement IoT solutions for smart manufacturing.

02Precision Casting

Established for years, with a monthly production output of tons.

The exceptional mechanical performance relies on top-notch casting quality. Introducing "Meehanite" process management to enhance casting quality, meeting various stringent requirements for precision machinery performance. Besides serving Taichung Precision Machinery and related businesses, we also have the capacity to supply premium castings to other machinery sectors.

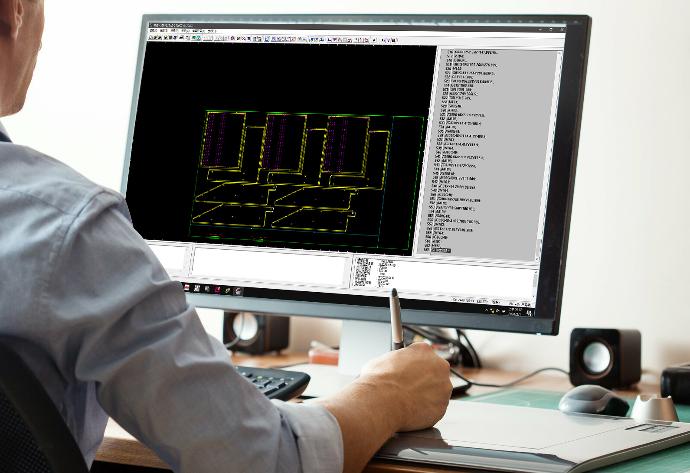

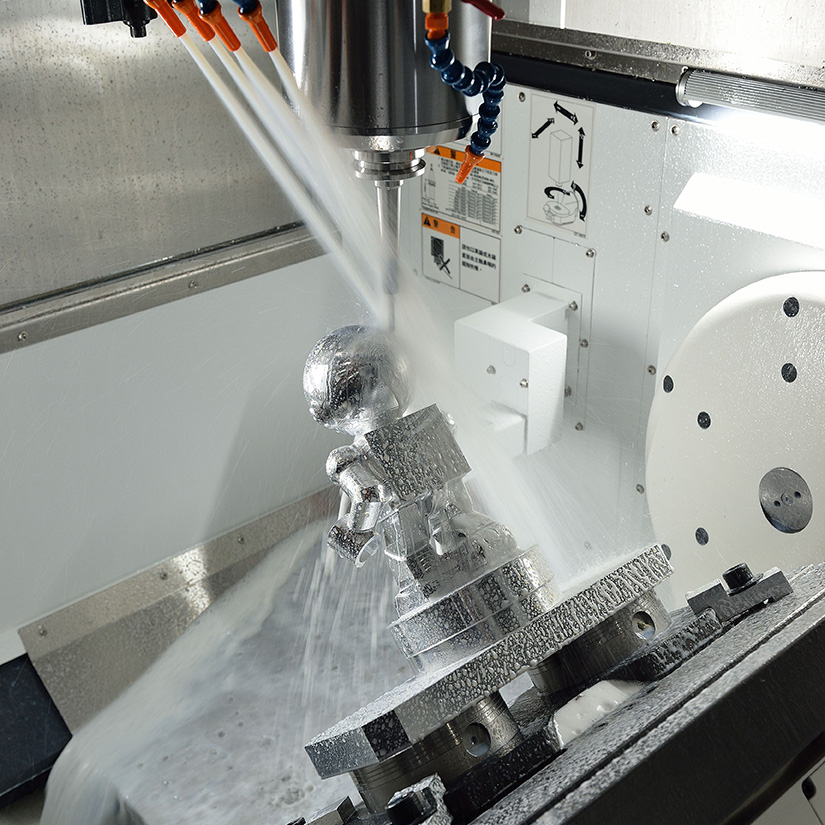

03Smart Machining

Our advanced production lines use FMS, IoT, and robotic arms to automate machining for over component types in small batches, ensuring precise processing with premium machines from Germany and Japan.

V4.1 、 V4.2

Smart machining production line.

V4.3 、 V4.4

Smart machining production line.

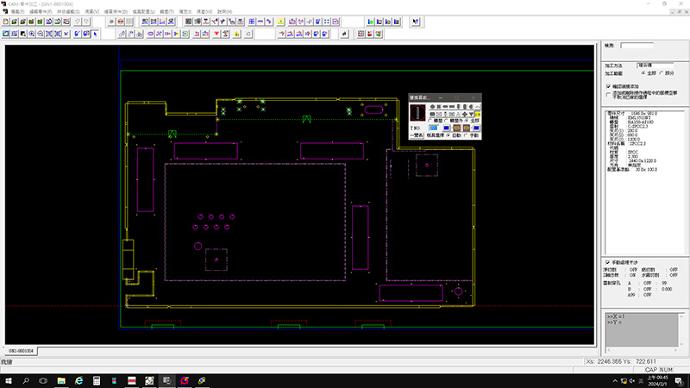

VSB (Victor Smart Box)

Production line screen-single machine

VSB (Victor Smart Box)

Utilization rate

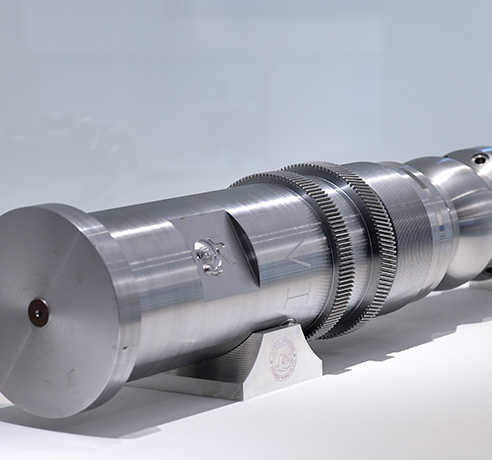

04In-House Key Component Production

We manufacture "Power Turrets" and "Spindle Heads" in-house under a consistent temperature and humidity environment to enhance spindle stability.

Precision Constant Temperature Processing

Mainly engaged in precision processing of lathe and center machine heads, as well as fully electric plastic machine head and tail plate processing.

Tool Post Assembly Area

Turret Production Line

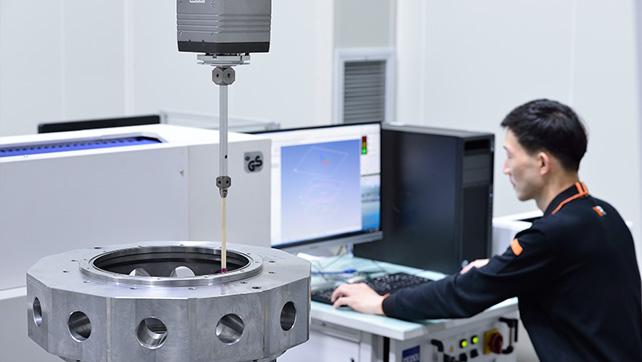

Coordinate Measuring Machine

Germany WALDRICH COBURG

5-Axis Machining Centers

Precision Processing Production Line

Germany WALDRICH COBURG

Gantry Grinding Machine

Japan YASDA

Horizontal Machining Centers

05Digital Sheet Metal Spraying

Established in

the Changhwa Lukang Plant

We've adopted Japan's AMADA simulated sheet metal manufacturing and powder coating equipment, creating a versatile digital factory. By combining sheet metal fabrication with coating, we ensure flexible order processing and prompt delivery.

Production Process

06Smart Assembly

The VSP smart, precise, and highly efficient production mode, combined with automated warehouse and AGV, integrates data management from the situation room.

Material flow has increased by 60%, saving 70 hours of manual handling time per month.

With a 6-story high automated warehouse featuring 9604 storage locations and 2 sets of automatic retrieval machines, combined with an embedded Autonomous Guided Vehicle (AGV) system, materials are automatically transported to designated locations after scanning orders in the warehouse. This significantly enhances production efficiency.

Three-dimensional measurement ensures component precision.

We utilize ZEISS 3D equipment to measure components such as heads, spindles, and gearboxes, ensuring the quality of machine tools.

Coordinate Measuring Machine