Features

Vturn-V560 Compact VTL Designed for Heavy Cutting

Following on from the Victor Taichung extremely successful range of horizontal lathes, our range of vertical lathes has been designed to meet higher roundness requirements.

Vturn-V760 High Rigidity and High Reliability VTL

With a maximum turning diameter of 760 mm (29.9") and a swing of 900 mm (35.4") the Vturn-V760 meets the

increasing demands for large size and/or heavy part turning. The standard Fanuc aP40i wide range motor along

with ZF gearbox provide high torque at extremely low spindle speeds.

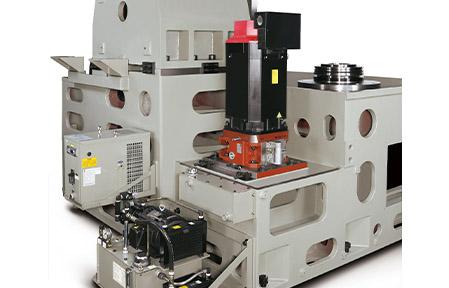

Vturn-V1000 High Reliability VTL with Turning Diameter 1000mm

Following the success of our Vturn-V760, with a swing diameter of 1100mm (43.3") and a maximum turning

diameter of 1000mm (39.4"), the VTL Vturn-V1000 with its powerful 45kW (60HP) spindle motor coupled to a 2

step Gearbox provides high torque at low rpm's.

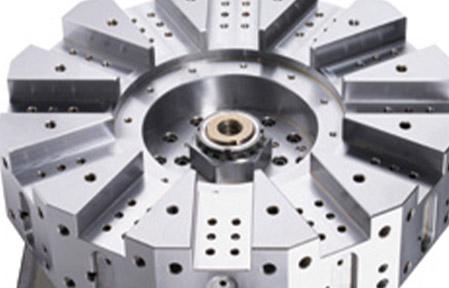

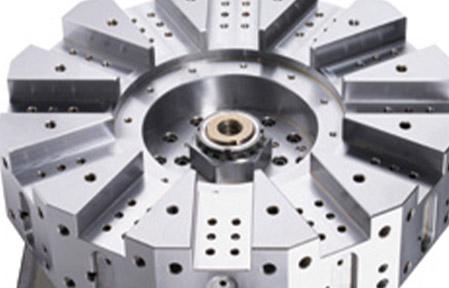

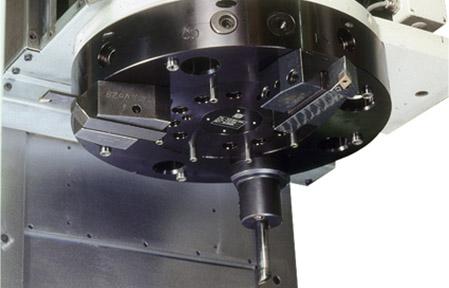

Vturn-V560 Vturn-V760 Fast Indexing Hydraulic Turret

- Curvic coupling for high accuracy positioning.

- Hydraulic clamping for heavy cutting.

- Fast indexing with bi-directional random selection provides quick tool selection.

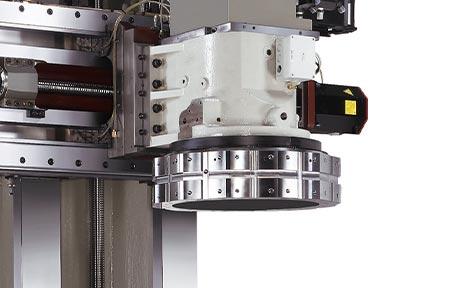

Vturn-1000 Bolt Mounted Turret (BMT-85)

- Fast indexing BMT-85 turret with bi-directional random selection for quick selection.

- Hirth coupling in included for high positioning accuracy.

Vturn-V560 Wide Span for High Rigidity

Moving column with 515 mm wide span sits on the machine base ensuring a stable structure for heavy cutting.

Vturn-1000 High Rigidity Spindle with NN Type Bearings

- NN type bearings featuring double rollers with double contact area facilitate heavy cutting and longer

surface life.

- 24" solid chuck as standard and available with bigger chuck up to 40".

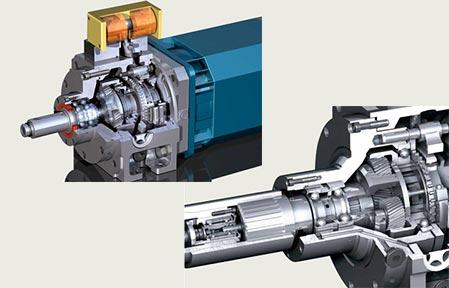

Vturn-V760 Wide Range Spindle Motor Coupled with Gearbox

- Fanuc wide range motor αP40i offers 22 kW (30 HP) output. Optional motor 30i offers even higher output 37 kW (50 HP)

- The German made ZF gearbox which lowers the base speed to 83 rpm (αP40i motor) provides the capability to efficiently machine the most exotic alloys at low rpm.

- The 2 stage gearbox also allows for the machining of smaller parts at higher speeds.

Vturn-1000 Powerful Spindle Motor Coupled with Gearbox

- Fanuc spindle motor α40i offers 45kW (60HP) output.

- German made ZF gearbox is included as standard to lower the base speed to 96 rpm for heavy cutting on steel parts with high torque 4490 Nm (3312 ft-lbf).

- 2 step gearbox facilitates higher speed turning on the smaller parts.

Vturn-V560 High Power and High Torque Spindle

- Encased in a heavily ribbed headstock for maximum heat dissipation.

- A wide range spindle motor delivers maximum torque at a very low spindle speed of only 216 rpm.

- 12" hydraulic chuck as standard with an optional 10" chuck available for use at higher spindle speeds up to 3500 rpm.

- NN type roller bearings featuring large contact areas which facilitate heavy cutting, whilst an angular thrust bearing absorbs the cutting forces.

- An optional C-axis spindle with 0.001 degree indexing is available along with a VDI turret which allows secondary machining operations such as milling and drilling to be performed in one set up.

Vturn-V760 High Power and High Torque Spindle

- Encased in a heavily ribbed headstock providing maximum heat dissipation.

- 18" solid chuck as standard and available with optional 15"/21"/24" chucks.

- NN type roller bearings featuring large contact areas which facilitate heavy cutting, whilst an angular thrust bearing absorbs the cutting forces.

- An optional C-axis spindle with 0.001 degree indexing is available along with a VDI turret which allows

secondary machining operations such as milling and drilling to be performed in one set up.

Vturn-V560 Box Slideways for Optimal Dynamic Stiffness

- A moving carriage with large base is fitted to the box slideways bolted on Z-axis column to ensure optimal rigidity and uniform cutting conditions at any location.

- 15/24 m/min rapid feed rate in X/Z axes bonded with Turcite-B and forced lubrication improve performance by eliminating stick-slip characteristics normaly inherent in plain contact surface.

- The counter balanced design featuring powerful servo motors and large diameter ballscrews guarantee minimal wear to the box slideways thus prolonging the machines service life.

- The Z-axis motor incorporates a brake which prevents the turret falling should a sudden loss of power occur.

Vturn-V560 Leakage Free Coolant System with Optimum Chip Disposal

- The rear disposal chip conveyor allows easy integration into a manufacturing cell.

- Coolant and chips are collected in the machine base, guaranteeing no coolant leakage during machining.

- The large coolant tank with a capacity of 260 litres minimizes heat build up during continuous production.

Vturn-1000 Integral Chip Disposal Without Coolant Leakage

- Rear disposal chip conveyor can be bolted and fastened on the machine base without sitting on the coolant tank so the tank can be removed separately and easily for maintenance.

- Optional Right Disposal chip conveyor is also available which can be useful for stand alone machines.

- Coolants and chips are collected by casted base guarantees no leakage onto the ground floor.

- Large coolant tank reduces the heat rise-up to affect machining accuracy.

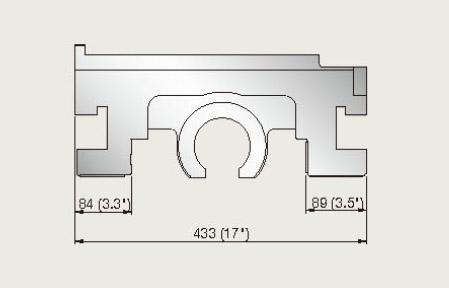

Vturn-V760 Wide Span Box Slideways

- The heavy column with a wide span of 850 mm (33.5) sits on the machine base providing a stable structure for heavy machining.

- The carriage for the hydraulic turret also features a wide span of 433 mm (17") ensuring the rigidity required for heavy machining.

- Z-axis motor of 7 kW (9.4 HP) ensures smooth operation and improves drilling capability.

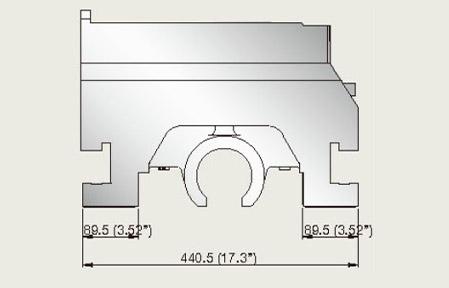

Vturn-1000 Wide Span Box Slideways

- The heavy duty column with a wide span of 995mm (39.2") attached to the machine base provides a stable

structure for heavy machining.

- The hydraulic turret is also designed with a wide span of 440.5mm (17.3) to ensure sufficient rigidity for

heavy machining.

- The 7kW (9.4HP) high torque Z-axis motor ensures heavy duty drilling capability

Vturn-V560 Meehanite® Cast Iron Structure

- The Meehanite® gray cast rod provides the structural stiffness and vibration damping properties which provide superior surface finishes and prolong the machines service life.

- The one piece box structure with box slideways provides the machine optimal structural rigidity.

- The steeply angled design of the machine base around the chuck and spindle areas minimizes swarf accumulation.

- The FEM (Finite Element Method) determined, optimized ribbed structure minimizes deformation during the machining operation.

Vturn-V760 Meehanite Cast Iron

- Supplied by Victor Taichung's own foundry, this Meehanite casting features superior vibration damping and high rigidity providing improved surface finishes

- All castinas are certificated by following Meehanite process for high quailtiy nodular gray iron.

Vturn-V760 Leakage Free Coolant System with Optimum Chip Disposal

- A Rear Disposal chip conveyor allows easy integration into a manufacturing cell.

- An optional Right Disposal chip conveyor is also available which is suitable for stand alone machines.

- The coolants and chips are collected by the cast base guaranteeing no leakage.

- The large coolant tank minimizes heat build up during continuous production

Reliable Fanuc 0i-TF Plus Control System

- The proven reliability of Fanuc 0i-TF Plus controller is combined with Victor's own designed PLC to offer the customer an integral control system with 10.4" LCD monitor for color graphic display.

- Large inside space design of electrical cabinet and fully protected cables assure optimal heat dissipation for long time machining.

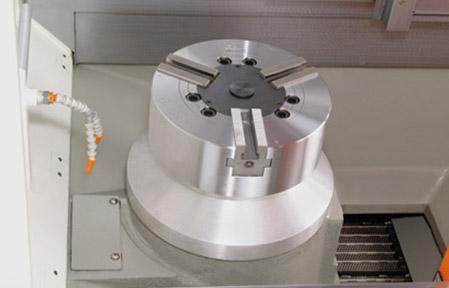

Solid Power Chuck

- Autostrong® hydraulic solid chucks are included on all lathes.

- Chuck is foot operated for safe and easy operation.

- Kitagawa® chuck (optional) can be also specified if required.

Chip Conveyor and Cart

Separate chip conveyor is positioned from the rear of machine to reduce machine width to facilitate line production.

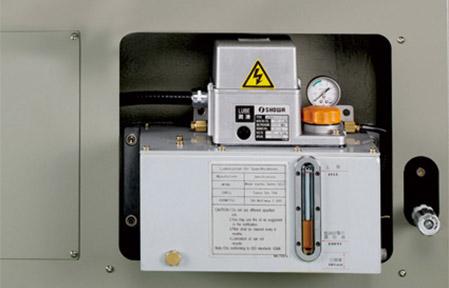

Victor's Lubrication Pump

Victor's own lube pump including Japanese-made pressure switch offers the required lubricants between contact surfaces of box slideways to ensure smooth and continuous movement.

Air Conditioner for Electrical Cabinet

To prolong the service life on the costly control components, air conditioner is installed to remove heat away from the electrical cabinet.

Manual Tool Pesetter (by Renishaw®)

The tedious time-consuming cuts to determine tool geometry can be reduced by manual tool presetter (M.T.P) With Renishaw® repeatable arm with RP3 probe is employed, the tool offset value is compensated automatically to the according parameters.

Detachable design enlarges the turning range on big diameter parts without interference.

VDI Turret with or Without Live Tooling

VDI tool holders provide an accurate and fast method of affixing tool holders to the turret disk. The round serrated shank tool holders fit into the tool pockets located on the face of the tool disc to achieve precise, rigid and secure locking of the tool holder. Live tooling option is also available by VDI turret model (CV option).

High Pressure Coolants

Higher pressure coolants help removing chips more efficiently to improve surface finish on the machined parts.

Accessories

Standard :

- Solid chuck with soft jaws

- Chip conveyor with cart (rear disposal)

- Automatic forced lubrication

- Fully enclosed splash guarding Tool holders (exch VDI / BMT tooling)

- 3 step warning light

- Fanuc 0i-TF Plus (10.4") control

- Remote MPG (handwheel) (except Vturn-V560)

- Oil cooler for gearbox (Vturn-V760 / V1000)

- Fanuc e-book (CD)

Optional :

- Bigger chucks (21" chuck/1700rpm, 24" chuck/1400rpm, 28" chuck/1200rpm, 32" chuck/1100rpm, 36" chuck/1000rpm, 40" chuck/800rpm)

- Oil skimmer

- Bigger spindle motor

- Renishaw tool presetter (detachable) (Max. 15" chuck for VT-V560, 24" chuck for VT-V760, 36" chuck for V1000)

- High pressure coolant

- Auto door

- VDI turret (except Vturn-V1000)

- Higher column (100mm more)

- Right disposal chip conveyor (for Vturn-V760/V1000)

- Higher outlet chip conveyor (for Vturn-V560)

- Detachable chip conveyor (to reduce the floor space when cleaning)

- Fanuc manuals