Features

Extreme Performance

First choice of heavy cutting and high torque output. The 3 axis high-rigidity box slideways and Victor's own Geared Spindle.

Concise Design with Aesthetic Full Coverage

Industrial design implements science, technology and creative art together. The beauty and usefulness of the unity, but it also seeks coordinated CNC machine tools and people, parts and the environment.

Match the necessary functions for processing according to market demand, reducing the functions that are not commonly used in general processing.

Chip Removal System Upgrade

- Standard In-machine spiral chip conveyor

- Standard Side-out spiral chip conveyor

- Standard Overflow separated water tank

Head Cutting Water System Design

- Standard Head coolant ring + lateral pipes by M-code, prevent chips from accumulating on the work table.

- Standard Air blow by manual and M-code.

- Standard LED lamp above spindle, installed in front of the head spindle to directly illuminate the tool processing area with no blind spots.

- Standard Auto door for magazine, prevents water and chip entering the magazine.

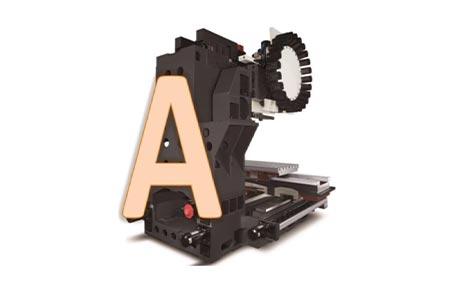

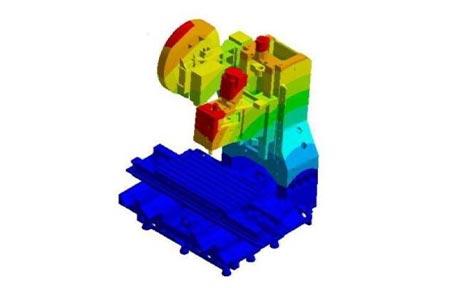

Rigidity Stable Accuracy

The rigidity of the new A-shaped column is increased by 15%, which can avoid the vibration caused by the cutting force during cutting, and it is more powerful during heavy cutting.

Shoulder Type Tool Magazine

Shoulder type tool magazine fixed support design, the weight of the tool magazine is directly carried by the base below, and the column will not tilt due to the weight of the tool magazine and tools. The Chain-type tool holder with multiple tool counts, optional can be freely mounted without affecting the accuracy of the column.

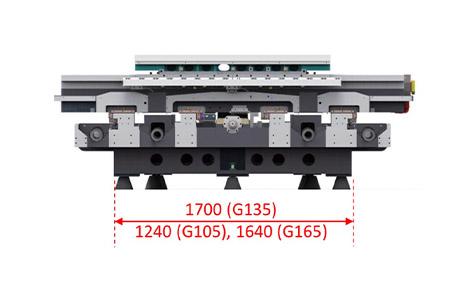

Optimized Box Slideways Span

When the heavy workpiece or the 4th axis rotary is placed on the high-rigidity table, the worktable don't deformed and affects the accuracy.

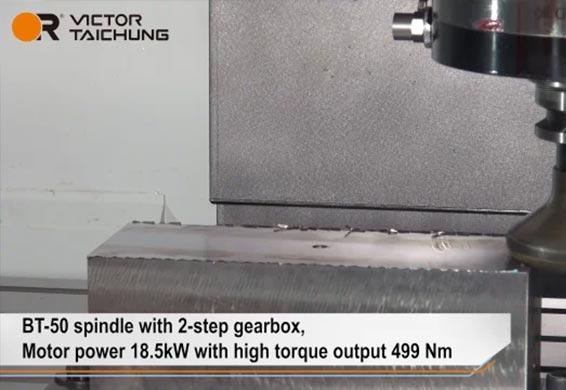

Cutting Ability

The axis high-rigidity improved cutting ability, it can greatly improve the processing accuracy and meet the high precision requirements.

New Design Geared Spindle

- Standard BBT50 taper, design offers smooth reliability at heavy cutting.

- Spindle cooling system standard removes heat efficiently and minimizes thermal deformation.

- Standard Process dynamic balance and low vibration.

- New design Angular encoder is attached on spin.

Accessories

Standard :

- Fully enclosed splash guard

- Fanuc 0i-MF Plus (10.4", type 1) control

- Spindle oil cooler

- Screw-type chip remover (left disposal)

- Bottom guarding flushing coolants

- Rigid tapping

- Remote MPG

- Hand tools and toolbox

- T nuts for table slot

- 3-step warning light

- Auto power off

- Leveling pads

Optional :

- Air conditioner for electrical cabinet

- Fanuc 0i-MF Plus (15", type-0) control

- Chip conveyor with cart

- Coolant through spindle (CTS)

- 32 or 40 tool magazin

- 4th/5th axis interface

- Auto door

- Table shower

- Oil skimmer

- Linear scales

- Air gun

- Coolant gun

- Stop block for special tools

- Auto tool length measurement

- Auto part measuring