System Development Background

High-precision lathes are typically used to machine high-accuracy and high-value components. However, the machining process of machine tools is affected by various factors such as structural heat sources, environmental variations, and tool wear, which may result in varying degrees of machining error. As a result, all finished workpieces often require full inspection for dimensional accuracy. Yet, both labor and the establishment of hardware/software inspection systems are costly. Additionally, due to declining birth rates, the overall working population is decreasing year by year, making it difficult for the traditional machine tool industry to recruit talent.

To avoid the production waste costs caused by abnormal tool conditions—such as overcutting of critical dimensions or workpiece damage—identifying the optimal tool replacement timing is key. However, many customers adopt a conservative approach by replacing tools early. Although this avoids machining loss from tool failure, it significantly increases tool maintenance costs. Furthermore, real-time monitoring of machining precision is rarely implemented; quality defects can only be detected after the machining is completed, leaving no room for in-process corrective action and increasing production time costs.

In lathe machining, multiple factors must be considered—including materials, parameters, tools, and process variations. Accurate machining quality and tool wear prediction require considering a wide range of conditions. However, current technological approaches often lack cross-condition applicability and are limited to specific scenarios. When processing conditions change, prediction performance declines significantly, making existing methods unsuitable for practical use. In contrast, AI-based prediction models, when supported by sufficient data, can maintain high accuracy under varying conditions. This calls for the integration of specialized AI R&D talent and machining process experts, along with the accumulation of extensive machining data to compensate for a lack of domain-specific experience.

System Structure Design

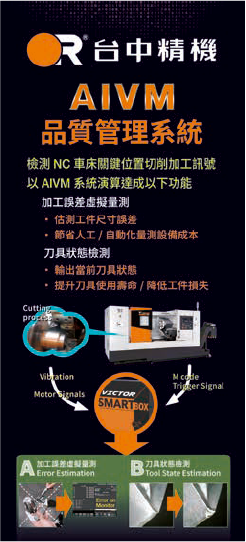

The AIVM Lathe Machining Quality and Tool Wear Prediction System utilizes data acquisition software to collect real-time cutting vibration signals and spindle current load variation signals during machining. Cutting vibrations reflect dimensional errors in the inner/outer diameters, surface roughness, and tool wear at the point of contact, while spindle current variations indicate cutting resistance during machining.

All critical machining signals are processed through an AI model to predict the dimensional errors of the current workpiece. Simultaneously, the model estimates the tool’s wear status. Upon completion of machining, AIVM can compute predictive results in a short time, greatly reducing manual measurement time. Based on the wear estimation, the system can determine whether to apply tool compensation or initiate automatic tool replacement, thereby extending tool life and reducing replacement frequency—ultimately improving production efficiency and lowering tool costs.

To build AIVM, accelerometer sensors must be installed near the cutting points on the spindle and turret. These sensors connect to data acquisition cards to read vibration signals. The data acquisition software aggregates vibration signals across channels and timestamps them. It also reads spindle current parameters based on controller versions and axis configurations. Key dimensional accuracy and tool wear conditions from cutting histories are collected as target variables for prediction. The segmented vibration and current load data are time-sequenced and stored in a non-relational database along with corresponding target values.

The AI model building module reads vibration and current load data from the database and performs preprocessing. To eliminate unit inconsistencies, time-domain signal data is normalized. Using Fourier Transform, time-domain signals are converted to frequency-domain signals and organized into training datasets. These datasets are then matched with the corresponding dimensional accuracy and tool wear targets. The refined datasets are used to train the initial AI model for the AIVM system.

When a customer purchases a new lathe, a small number of machining data samples must be collected based on the customer's production workflow and defined target outcomes. AIVM then performs fine-tuning on the base model using LoRA (Low-Rank Adaptation), which adjusts only a portion of the model parameters. This allows AIVM to quickly adapt to the customer's current machining conditions with minimal adjustment time, enabling rapid deployment on actual production lines.

System Applications and Benefits

The AIVM system helps customers reduce the need for manual inspection while improving production efficiency and product quality. By precisely controlling machining accuracy, it ensures consistent dimensional stability throughout the process, minimizing scrap caused by large dimensional variations. It significantly reduces production losses and overall costs, including tool, workpiece, labor, and automated inspection equipment expenses.

AIVM adds value by enhancing customer competitiveness and production line automation efficiency. By predicting machining errors and feeding that back into tool compensation values, AIVM keeps machining precision within tolerable limits. It can detect tool damage features and automatically switch to backup tools, enabling long periods of uninterrupted operation. This reduces downtime for manual correction or tool replacement, improving overall efficiency to meet future industry demands for high stability and environmental responsibility in machine tool manufacturing.

Communication Structure of the AIVM Lathe Machining Quality and Tool Wear Prediction System

2025/04/23