Features

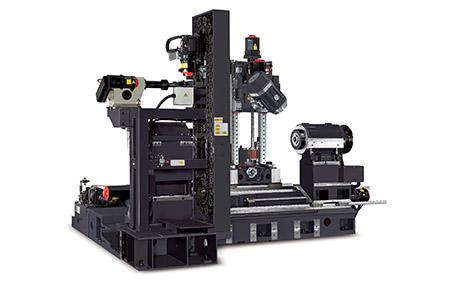

Extreme Performance

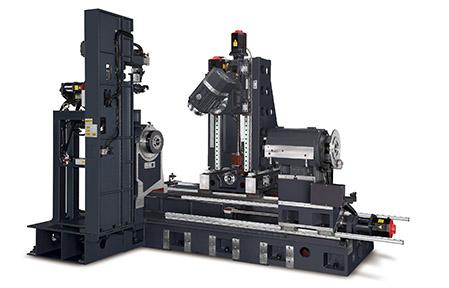

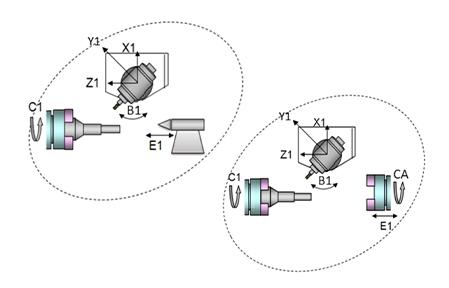

First choice of Turning & Milling in one set-up Mulit-Tasking machinery with twin built-in spindles and swivel head built-in milling spindle.

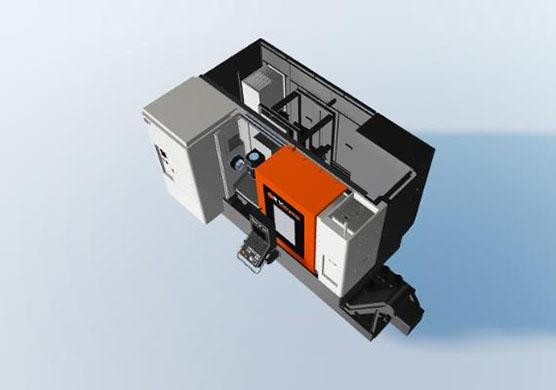

Concise Design with Aesthetic Full Coverage

Industrial design implements science, technology and creative art together. The beauty and usefulness of the unity, but it also seeks coordinated CNC machine tools and people, parts and the environment.

Match the necessary functions for processing according to market demand, reducing the functions that are not commonly used in general processing.

Chip Removal System Upgrade

- Standard Head coolant ring prevent chips from accumulating on the work table.

- Standard Coolant flush to the bottom of Z-axis covers.

- Standard CTS, coolants through milling spindle for high pressure turning.

- Standard Lube hybrid lubrication system.

- Standard ATP, automatic tool presetter.

Improve User Friendly

- New design 15 inch big screen and L-form control panel, using an ergonomic controller will help your pain. (Siemens controller 19”).

- Touch screen and Qwerty keyboard, operates similar to your personal computer.

- Optimize of the controller to improve production efficiency.

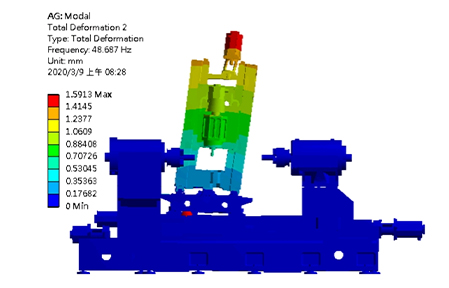

Rigidity Stable Accuracy

The rigidity of the new Box base is increased by 8%, which can avoid the vibration caused by the cutting force during cutting, and it is more powerful during heavy cutting.

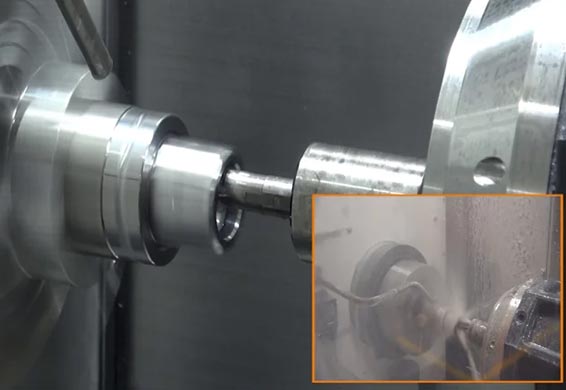

Cutting Ability

The axis high-rigidity improved cutting ability, it can greatly improve the processing accuracy and meet the high precision requirements.

New Design Orthogonal Machine

High-speed, high-accuracy machining by DONE IN ONE processing, and high-rigidity construction and powerful spindles for higher productivity.

The 90° orthogonal machine design of the VMT series provides a large machining area plus high-rigidity machine construction.

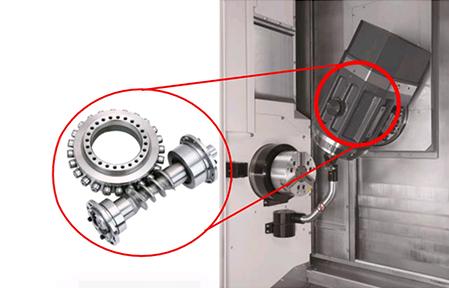

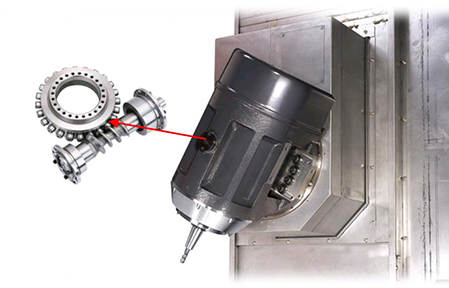

One Set Up, High Rigidity

Roller geared B-axis swivel head for high rotating speed with high rigidity.

Milling spindle HSK-T63, 12000 rpm implements 4+1 axis (mill and turn) machining in one set up.

High Productivity

- Standard NC servo tailstock The operator can set the tailstock position on the setup screen and move the tailstock to the correct position by menu-key or M-code.

- X200, X260: MT#5 Max. thrust 7 kN (713 kgf) (1574 lbs).

- X360, X400: MT#5 Max. thrust 10 kN (1019 kgf) (2248 lbs).

- Optional Sub spindle Perform continuous machining of first and second processes.

Accessories

Standard :

- Fanuc Oi-TF PLUS (15", type 0) control with iHMI + AICC + MGI

- Hydraulic chuck with soft jaws

- Chip conveyor with cart

- Automatic Tool Presetter (ATP by Renishaw®) for milling spindle

- Coolant flush to the bottom of Z-axis covers

- Coolants through milling spindle for high pressure turning (7 bars/60Hz)

- Digital tailstock

- LHL (Lube Hybrid Lubrication) system

- Spindle oil cooler

- Fully enclosed splash guarding

- Hand-wheel (Pulse generator)

- 3 step warning light

- Handy air gun

Optional :

- Subspindle

- KITAGAWA® hydraulic chuck

- Hard jaws

- Coolant Through Spindle (CTS)

- Steady rest

- High pressure coolants

- Bar feeder interface

- Part catcher (X200/X260)

- Hand-wheel (remote MPG)

- Air blow system

- Auto door

- Fanuc manuals

- Fanuc 31i-B5 Plus control for

- Test bar for accuracy calibration

- Coolant gun

- Siemens ONE (19") control