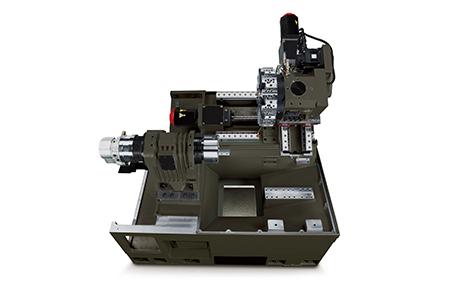

Extreme Space

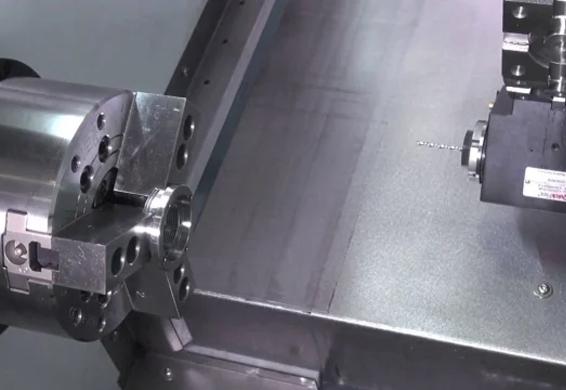

First choice of Narrow Lathe with High Precision. The 2 axis high-rigidity, high-precision roller linear rail and roller-type rolling, and Victor's own belt spindle.

Concise Design with Aesthetic Full Coverage

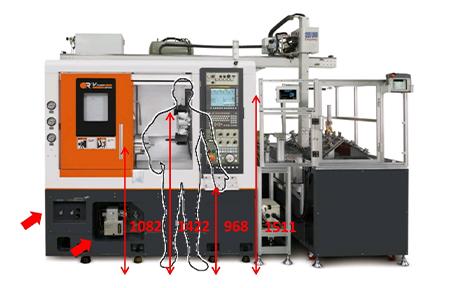

Industrial design implements science, technology and creative art together. The beauty and usefulness of the unity, but it also seeks coordinated CNC machine tools and people, parts and the environment.

Match the necessary functions for processing according to market demand, reducing the functions that are not commonly used in general processing.

Functional Equipment Upgrade

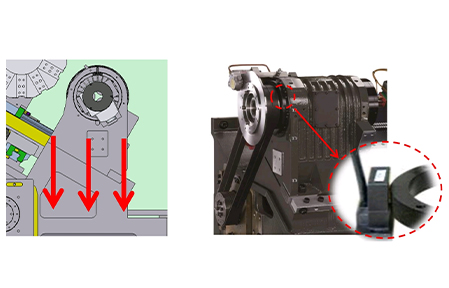

- Standard Turret coolant prevent chips from accumulating on the work space.

- Standard Coolant flush to the bottom of Z-axis covers.

- Optional Automation peripheral equipment.

Improve User Friendly

New design 10.4 inch screen vertical-form control panel, using an ergonomic controller will help your pain.

Qwerty keyboard,operates similar to your personal computer.

Optimize space lubricating oil and hydraulic solenoid valves are installed on the front, which easy operability and improves efficiency.

Rigidity Stable Accuracy

The rigidity of the new Box base is increased by 10%, which can avoid the vibration caused by the cutting force during cutting, and it is more powerful during heavy cutting.

Cutting Ability

The axis high-rigidity improved cutting ability, it can greatly improve the processing accuracy and meet the high precision requirements.

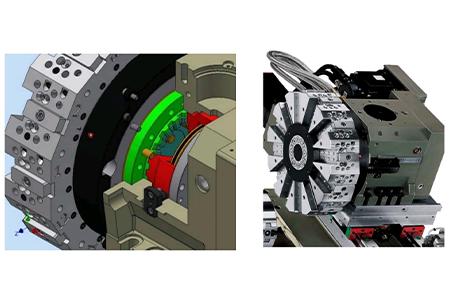

High Productivity

The Servo driven turret indexing time 0.9 (T-T, opposite). Milling turret by BMT (bolt mounted tooling) for high static rigidity.

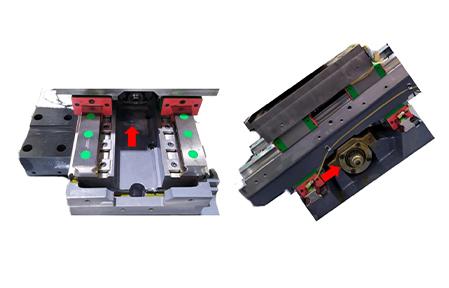

3-piece Coupling

Standard 3-piece coupling design without turret disk up/down affords high pressure coolants without leakage during indexing.

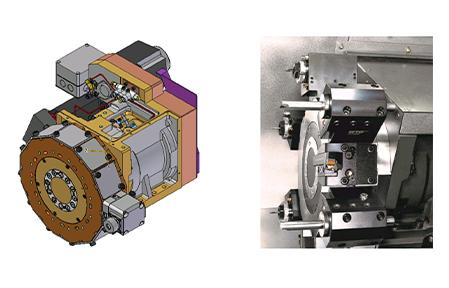

New Design Belt-Type Spindle

Heavy and light high-power spindle design: belt-type spindle, matched with high-power output spindle, is not inferior in general heavy cutting.

Standard motor placed inside remove spindle cartridge, support angular contact bearing (smaller contact angle for high rpm with less heat built-up) and spindle length is shortened.

Standard process dynamic balance and low vibration.

Optional C axis spindle with magnetic speed sensor as position coder to ensure accuracy 0.01°.

Features

Accessories

Standard :

- Fanuc 0i-TF Plus (10.4") with Manual Guide i

- Hydraulic chuck with soft jaws

- Chip conveyor (rear disposal)

- Fully enclosed splash guarding

- Tool holders (only for standard turret)

- Coolant flush on Z-axis cover

- 3 step warning light

Optional :

- Manual tailstock with power quill

- Chip conveyor (right disposal)

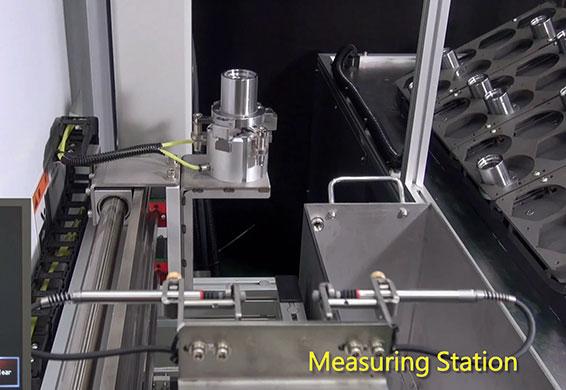

- Manual tool presetter

- Auto tool presetter

- Parts catcher (swing type)

- KITAGAWA® power chuck

- Air conditioner for electrical cabinet (Panel cooler)

- Higher pressure coolants

- Bar feeder interface

- Air blow

- Oil skimmer

- Oil mist collector

- Hard jaws

- Tailstock center

- Auto door

- Small spindle bore (Ø42 mm, 6000 rpm)

- Large spindle bore (Ø66 mm, 4000 rpm)

- C-axis

- Robot system