Features

NH5000

Extreme Performance

New Generation High speed Machining. The 3 axis high-rigidity, high-precision roller linear rail and roller-type rolling, and Victor's own spindle.

Concise Design with Aesthetic Full Coverage

Industrial design implements science, technology and creative art together. The beauty and usefulness of the unity, but it also seeks coordinated CNC machine tools and people, parts and the environment.

Match the necessary functions for processing according to market demand, reducing the functions that are not commonly used in general processing.

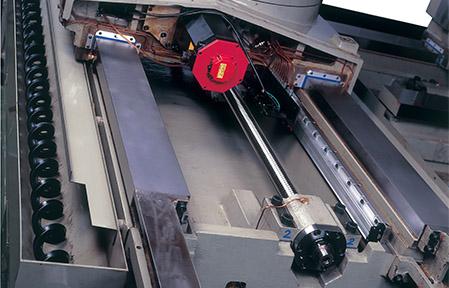

Chip Removal System

- Standard In-machine four screw chip conveyor

- Standard Side-out chip conveyor

Head Cutting Water System Design

- Standard Head coolant ring + lateral pipes by M-code, prevent chips from accumulating on the work table.

- Standard Auto door for magazine, prevents water and chip entering the magazine.

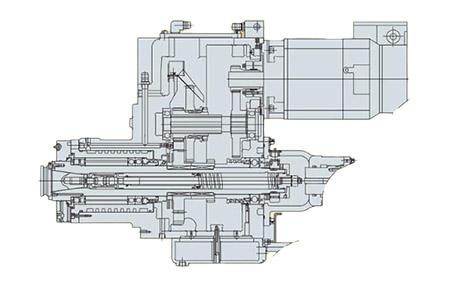

Rigidity Stable Accuracy

The rigidity of the new T-shaped column is increased by 13%, which can avoid the vibration caused by the cutting force during cutting, and it is more powerful during heavy cutting.

Support is closer to cutting area for higher cutting rigidity. This area is removed to reduce the column weight and inertia for quicker response.

Feature New Design

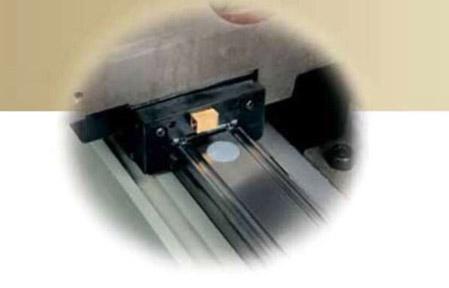

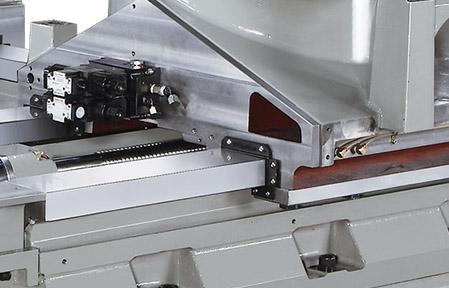

Roller linear rail uses KK-level protection, that is, two oil scrapers and a metal scraper are added on both sides of the slide rail, and a set of dust-proof sheets are also added under the slider to block foreign objects Or cut water into the slide rail.

Feature New Design

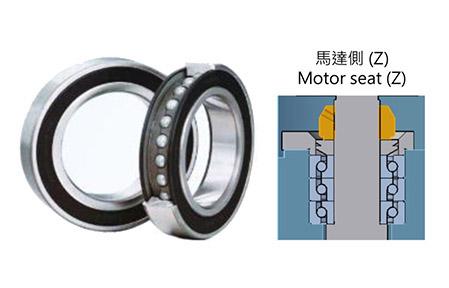

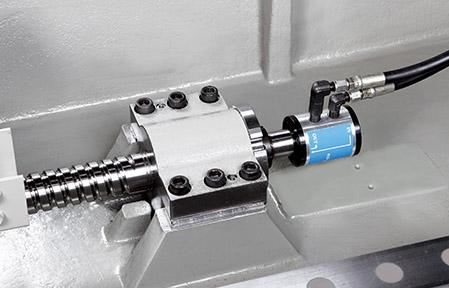

New sealed bearings + 3&3 supported for 3 axes, Prevents cutting water, foreign objects from entering and causing bearing damage and grease loss.

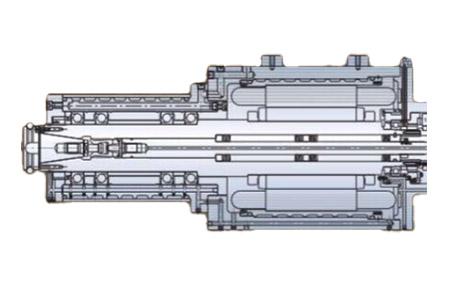

New Design Direct Drive Spindle

Heavy and light high-power spindle design: direct drive spindle, matched with high-power output spindle, is not inferior in general heavy cutting.

- Standard BBT40 tapers, design offers smooth reliability at high speed.

- Spindle cooling system standard removes heat efficiently and minimizes thermal deformation.

- Standard Process dynamic balance and low vibration.

- Optional Oil-air lubrication for 15,000 rpm spindle.

H400

Rapid Feed Rate 48/48/48 m/min (1890/1890/1890 IPM)

- 3-axis moving column design features high rapid feed rate 48 m/min (1890 IPM) for 3 axes to reduce tool changeover time.

- Axis acceleration 0.7G/0.7G/0.7G with high power output 4.5/5.5/4.5 kW (6/7.4/6HP) reaches highest machining efficiency.

- Steel type telescopic cover design assures long service life.

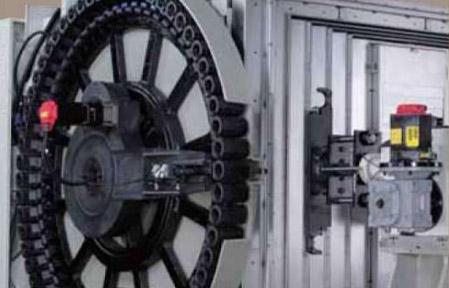

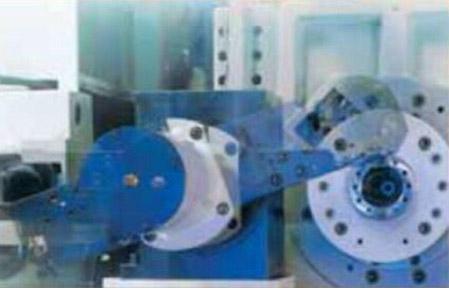

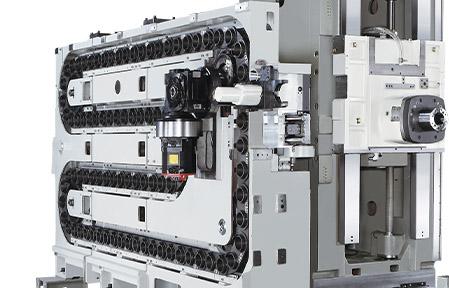

Servo Driven ATC and Tool Magazine

- Front mounted ATC to reduce machine width.

- 40-tool magazine with twin arm type ATC offers quick changeover time 4.5 seconds (chip-to-chip) for BBT-40 (BCV-40) tooling.

- Both ATC and magazine are servo driven to assure higher reliablity and longer service life.

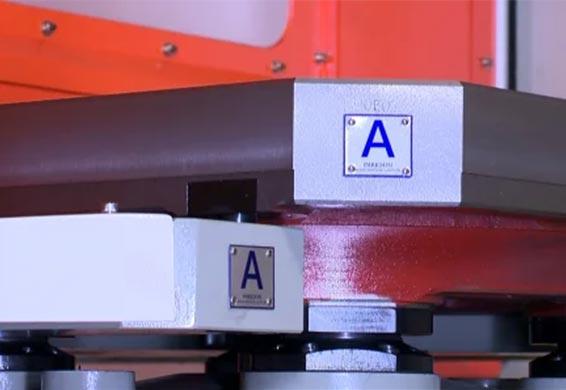

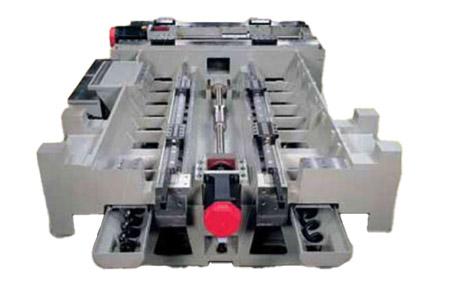

High Speed Pallet Changer APC

- Rotary type APC for quick pallet exchange.

- 4 ground cone shaped taper pins and bushings ensures high accuracy and repeatability throughout entire service life.

- Air jets are blown through cones assure pallet clamping and chip removing.

- Extenal pallet can be rotated manually.

- Pallet loading 400 kgs (880 lbs).

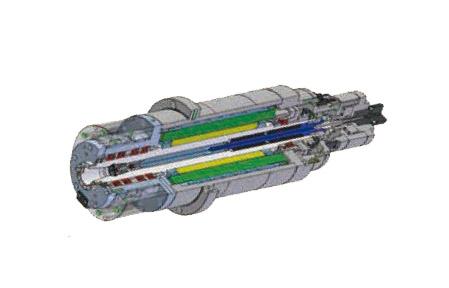

15000 rpm Built-in Spindle

- Built-in spindle avoids belt vibration to affect machining quality.

- Dual winding (low/high winding) with power output 18.5/22 kW (25/29.5 HP) further reduces cutting time.

- 4 pcs front bearings enhance cutting rigidity.

- Oil-air lubrication for long service life.

- BIG PLUS BBT-40 (BCV-40) tooling (compatible with BT-40 (CT-40) tooling) for sufficient tool clamping at high rpm.

User Friendly Design

- Rotary control panel with large keypads for easy

operation. - Spindle oil cooler, pneumatic and lubrication systems are located in the rear location for easy maintenance.

Efficient Disposal on Coolants and Chips

- Fixed pallet design with bottom flushing coolants assures minimal coolant leakage and chip build-up.

- Rear disposal chip conveyor utilizes easy layout for line production.

H500/H500HS

Built-in Spindle

- Built-in spindle avoids belt vibration to affect machining quality.

- Dual winding (low/high winding) with high power output further reduces cutting time.

- Air curtain for extra spindle protection.

- 6000 rpm, 11/15 kW (15/20 HP) for Vcenter-H500.

- 15000 rpm, 18.5/22 kW (25/29.5 HP) for Vcenter-H500HS.

Durable Tool Changer

- Side mounted 40-tool magazine with twin arm type ATC offers quick changeover time 8.5 second (chip-to-chip) for BT-40 (CT-40) fooling and 10.6 seconds for BT-50 (CT-50) tooling.

- ATC unit has been designed with minimal maintanance with the use of hydraulic motor to ensure stability and longer service life.

Symmetrical Design for Minimal Heat Growth and Chips Build-up

- Symmetrical machine design with steep angular splashguards inside minimizes the thermal growth on machine accuracy.

- Twin screw-type chip removers have been fitted to help remove chips out of the machining area to the machine front through the assistance of high pressure coolants.

- Front positioned chip conveyor for easy chip clean-up.

High Speed Pallet Changer APC

- Rotary type APC for quick changeoover.

- 4 ground cone shaped taper pins and bushings ensures high accuracy and repeatability throughout entire service life.

- Air jets are blown through cones assure pallet clamping and chip removing.

- High loading capacity 800 kgs (1760 lbs).

Strong Machine Structure

- Meehanite® casting from Victor Taichung's licensed foundry for maximum damping and strength.

- One piece bed castings with triangular structure and heavily ribbed column minimizes distortion during heavy cutting.

- Low table height reduces the bending moment for high positioning accuracy.

- Curvic coupling is used for table indexing and offer high repeatability.

High Rigidity and High Damping Guideways

- Oversized NRS style linear guideways ensure each axis can absorb the most extreme of cutting forces.

- Ballscrew holders are cast into the machine base to ensure a constant support over the entire machine life.

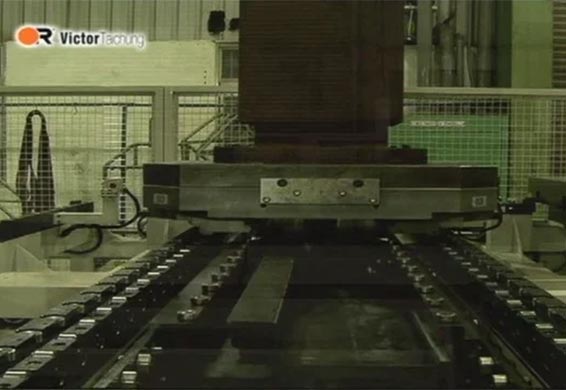

H630HS

High Rapid Feeds 48/48/48 m/min (1890/1890/1890 IPM)

- "T"-shape structure with Meehanite® casting from Victor Taichung's licensed foundry ensures maximum damping and strength.

- Roller type linear guideways enhance the structural stiffness by absorbing the extreme cutting forces generated by high speed machining.

- Heat in the ballscrews generated by high feed rates is removed by 'Through Ballscrew Coolant' feeds.

- Ballscrew holders are cast into the machine base enhances a constant supports.

10000rpm Built-in Spindle 30 kW (40 HP)

- BigPlus BT-50 built-in spindle avoids belt vibration to affect machining quality.

- Dual winding (low/high winding) with high power output 25/30 kW (30/40 HP) further reduces cutting time.

- Oil-air lubrication assures long service life.

Servo Driven Tool Magazine

- 60 tool magazine with twin arm type ATC offers quick changeover time 7.5 seconds (chip-to-chip) for heavy BBT-50 (BCV-50) tooling.

- Less heat generated in comparison as hydraulic system assure higher reliability.

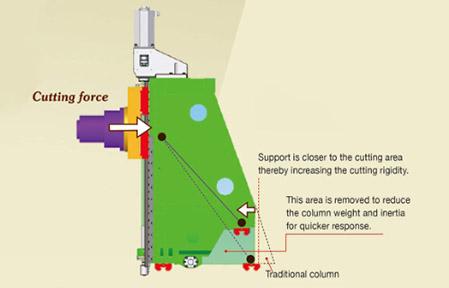

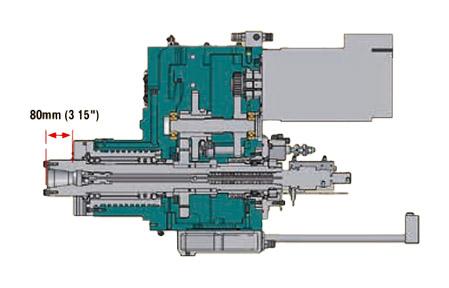

Slant Style Column Design

- An innovative design has a shorter distance from the spindle to the rear supporting guideways enhancing the cutting stability.

- Column responds more dynamically due to the reduced weight and inertia.

High Speed Pallet Changer APC

- Rotary style APC driven by servo motor reduce overall cycle time.

- 4 ground cone shaped taper pins and bushings ensures high accuracy and repeatability throughout entire service life.

- Air jets are blown through cones assure pallet clamping (air sealing detection).

- Hydraulic interface for APC (optional) powered through the B-axis mechanism facilitates auto part clamping.

- High loading capacity 1200 kgs (2640 lbs).

H630HD

Hydro-dynamic Box Slideways

- 50mm (2") large diameter ballscrews with 10mm (0.4") pitch provide high torque at high rapid feed rates of 24m/min (945 IPM) on all 3 axes.

- Large contact surfaces fully support both axial and lateral loading to prolong machine accuracy in heavy duty machining of hard materials.

- Higher damping with the use of bonded Turcite® eliminates local stick-slip for improved finish and longer tool life.

Hand Scraping

The traditional method of handscraping remains the most effective way of ensuring squareness and flatness in machine tools using plain bearing linear ways. With 60 years experience in building machine tools using this traditional manufacturing manner, our understanding of the critical factors that ensure accuracy and durability are second to

none. Highly skill personnel, trained in-house, are employed to make sure this handscraping is done to perfection.

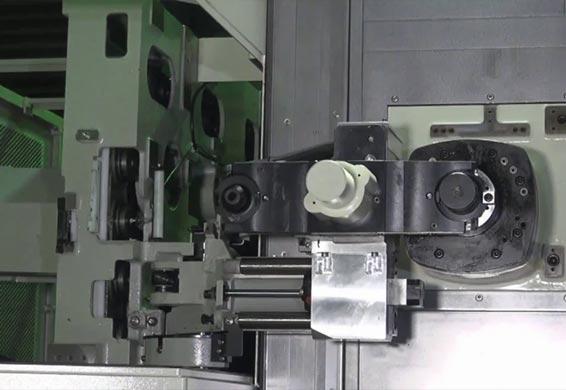

Tool Arbor Cleaning System (Rotating Tool Pocket with Brushes)

Intermediate tool pot for cleaning tools during tool changes ensures tool arbor is free from swarf and prevents damage to spindle taper and tools, which would otherwise degrades machining precision. Also ensures better mating between tool arbor and spindle taper for improved tool tip runout.

Servo Driven Tool Magazine

- Servo driven tool magazine with less heat generation than hydraulic type assures high reliability.

- 60 tool magazine covers wide range of applications.

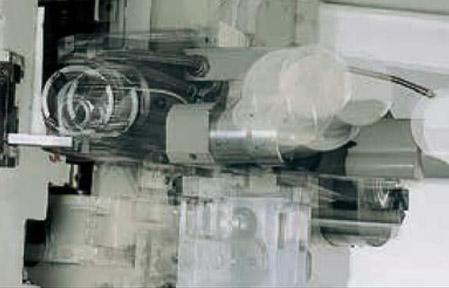

Two-step Geared Spindle Head

- The 2-step gearbox coupled with 22 kW (30 HP) spindle motor offers maximum torque output 902 Nm (665.2 ft-lbf) giving unrivalled metal removal rates at low spindle speed 196 rpm.

- Rotary joint is included as standard and ready for CTS retrofitting.

- Long overhang design spindle reduces the tool length for higher rigidity. The roller type bearings are used for rear bearings even enhance cutting capability.

- Oil cooling to the spindle and gearbox maintain low bearing temperature for extended spindle life.

High Pallet Loading 1200 kg (2640 lbs)

- High B-axis mechanism with deep slope helps reduce chips built-up on X-axis covers.

- Available with optional hydraulic interface which allows the power to go through the B-axis mechanism from bottom.

- CNC pallet (option) with continuous 0.001° indexing is available by unique feature of Roller-CAM-Drive mechanism guarantees higher rigidity without existence of worm-gear backlash for full 4 axis.

ECO Design

- Control panel is mounted on the front lateral guarding, so the operator can easily see inside and operate the machine after opening the door to the right.

- External pallet can be manually rotated on APC with pedals.

H1000

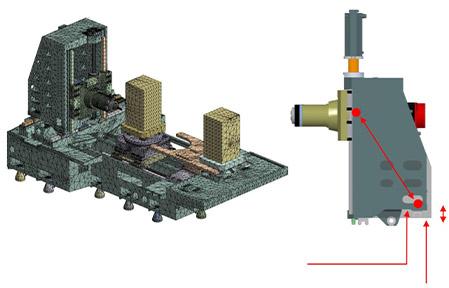

Advanced Design

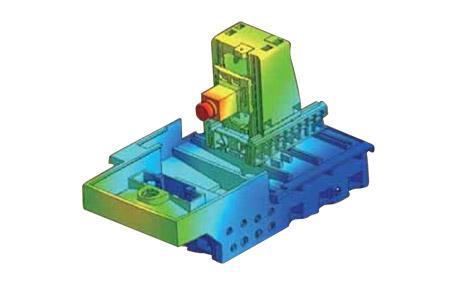

Through the use of advanced CAD and CAE, our R&D laboratory makes computer simulations of the machine's structure for deformation and vibration during operation, which can be later confirmed by computer aided testing. Areas of high stress concentration or excessive thermal growth are pinpointed on the drawing board, so they are eliminated at an early stage and optimum machine life can be guaranteed.

Strong Machine Structure

Heavy duty Meehanite castings are used in the bed and column for maximum damping and strength. One-piece bed casting with triangular structure and heavily ribbed column minimise machine distortion during operation. Boxways are cast into the bed and column so no distortion occurs due to thermal differences between the slide-ways and machine casting! This maintains alignment of the ways throughout the machine life.

Improved Positioning Accuracy

Table height is kept low to reduce the bending moment so that improved positioning accuracy is possible under heavy cutting.

A curvic coupling in table indexing offers excellent repeatability.

All axes motors are direct coupled with flexible couplings so that no transmission vibrations are present. For Y-axis counter balancing is replaced with high powered 7 kW (9.4 HP) servo-motor with built-in brake, for smoother travel and finer positioning accuracy.

Machine Operation Panel

Operator friendly control panel makes manual operation simple which includes remote MPG to ease machine set-up and ergonomic layout to maximize operator efficiency. Control panel is CE compatible and is built to withstand the most arduous shop floors! Air cond for control cabinet maintains temperature control to ensure durable operation. High level of PLC integration with numerous safety features ensures smooth and safe operation.

Minimizing the Effects of Thermal Growth

Symmetrical design and construction means heat generation is limited to minimise the effects of thermal growth on machine accuracies. Double-anchored ballscrews are pretensioned during assembly to absorb thermal growth without effecting accuracy.

Effective chip evacuation from the machining area improves heat dissipation from the working area while spindle oil cooling prevents excessive spindle growth.

Heavy Duty Spindle with Integral 2-speed Gearbox

Vcenter-H1000 have been designed to handle large workpieces in a single set-up. The 2-speed gearbox coupled with 18.5/22 kW (25/29.5 HP) spindle motor offers maximum torque output of 1072 Nm (790.6 ft-lbf) giving unrivalled metal removal rates.

Spindle is supported with heavy duty roller bearings with large contact areas that easily handles large axial and radial loads.

Oil cooling to the spindle and gearbox maintain low bearing temperature for extended spindle life.

Durable Tool Changer

Twin arm type ATC performs better over continuous tool changes compared with disc type tool changers, while at the same time offering fast tool change.

The ATC mechanism and tool magazine are both driven by durable hydraulic motors which ensures increased stability and longer service life. The entire unit is designed for minimum maintenance.

Maximum Flexibility with Parallel Type APC

Parallel pallet changer offers increased machining area for oversized parts without interference with machine guarding. Pallets can be easily removed from the APC to make workpieces set-ups trouble free. Additional pallets can be set-up and kept in storage until needed. This system also enables swift and simple integration into FMS lines.

H Series Machine Options

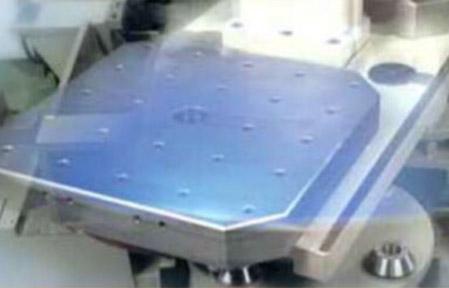

CNC Table with 0.001° Continuous Indexing

0.001° continuous indexing is available on the B-axis for simultaneous 4-axes machining. The servo-motor is upgraded so that plenty of power is pro vided in machining complex forms and contours.

Table indexing time is also reduced to only 0.2 sec per deg. Rotary encoder is included as standard for improved positioning accuracy.

Coolants Through Spindle (CTS)

For improved drilling or boring capability, coolants with high pressure can be forced through the center of the spindle and flow through the tool directly to the cutting area. To ensure the long and reliable running of this system, fine particles produced during machining must be filtered out to prevent the damages to the spindle. Victor Taichung offers several types of filtration systems to meet different requirements in machining.

Table Shower (Niagara Coolants)

To enhance chip removal around the workpiece and reduce thermal growth supplies a table shower system is available which flood coolant from above.

The strong coolant flow ensures the workpiece and guards are swept clear of cutting chips.

Linear Scales (Standard on Vcenter-H1000)

Linear scales on all 3 axes offer exceptional positioning accuracy, up to 0.005 mm over full stroke. Heidenhain® or FAGOR® linear scales with a thermal behaviour similar to that of the machine are selected, so that thermal expansion can be compensated for further enhancing repeatability.

Sealed encoders with durable aluminum housing offer improved reliability and service

life. This option is included as standard for Vcenter-H1000 to guarantee the consistent accuracy.

Expandable Tool Magazine

Modular design allows from 60 to 120 tools to be held in tool magazine.

Since the magazine is made up of cast-sections it is easy to slot in additional sections to expand tool capacity on site!

Workpiece Measurement

To reduce time spent setting workpiece positions and then manually inspecting finished parts, which would be better invested in machining, automatic workpiece measurement is availablewith the use of Renishaw MP-10, OMP-60 or RMP-60 measuring probes.

Workpiece position can be identified with the probe and work offsets automatically updated, enabling parts to be made right first time. During batch production in-processing checking can be performed on the machine, while for optimum accuracy in machining part inspection can be done after roughing so that finished part can maintain tight tolerances.

Auto Tool Length Measurement

To reduce tool set-up times and improve machine operator interface, Victor Taichung offers Renishaw tool measurement system. Using the Renishaw TS-27R probe or NC-4 non-contact tool setter, the tool length and diameter values can be automatically inputted into the tool offset values once the tool is tipped off the probe. This system is ideal for batch production where tools need to be constantly changed or replaced.

Multi-face Table (Tombstone Fixture)

T-slotted or bolted fixture block allows a variety of parts to be clamped offering improved productivity over vertical machine centres. Used in conjunction with standard B-axis pallet allows more parts to be set-up at a time!

Single Cell FMC or FMS for Unmanned Operation

For HS high speed series HMC with rotary type APC, pallet-pool design with 6 pallets and traverse mechanism composes a compact cell for unmanned operation. 12 pallets can be easily built up by two floors of pallets at the same floor space.

For HD heavy duty series HMC with parallel type APC, FMC is composed by multiple pallets and RGV (Rail Guided Vehicle) for unmanned operation.

Accessories

NH5000

Standard :

- 1° indexing table

- Spindle oil cooler

- Fully enclosed splash guard

- Manual pulse generator (remote type)

- Hand tools and tool box

- Scroll type chip remover

- Built-in work lamp

- Programming end light

- Leveling blocks

- Automatic pallet changer

- Spindle load meter

- Rigid tapping

- Table shower system

- Chip conveyer with cart

- Handy air gun

- Handy coolant gun

- Fanuc e-book (CD)

Optional :

- Air conditioner for electrical cabinet

- CNC table with 0.001 continuous indexing

- Coolant Through Spindle (CTS)

- 60, 90 tool magazine

- 15000 rpm spindle

- Hydraulic interface on pallet

- T-slot pallet

- Tool length measurement

- Workpiece measurement

- Linear encoder feedback

- Multi-face table (Tombstone fixture)

H Series

Standard :

- 1° indexing table

- Spindle oil cooler

- Coolant tank

- Fully enclosed splash guard

- Manual pulse generator (remote type)

- Hand tools and tool box

- Scroll type chip removers (except Vcenter-H400)

- Built-in work lamp

- Programming end light

- Leveling block

- Automatic pallet changer

- Spindle load meter

- Oil skimmer

- Rigid tapping

- Air conditioner for electrical cab

- Chip conveyer with cart

- Handy coolant gun

- Fanuc e-book (CD)

- Handy coolant gun

Optional :

- Table shower system

- Coolant Through Spindle (CTS)

- CNC table with 0.001° indexing

continuous - 60, 90, 120 tool magazine

- T-slot pallet

- Tool length measurement

- Workpiece measurement

- Linear encoder feedback

- Multi-face table (Tombstone fixture)

- Air blow system

- HSK-A63 tooling (Vcenter-H400/H500HS)

- 20000 rpm spindle (Vcenter-H400/H500HS)

- Hydraulic interface on APC (Vcenter-H400/H500HS/H500/H630HS)

- Fanuc manuals

- Handy air gun