Features

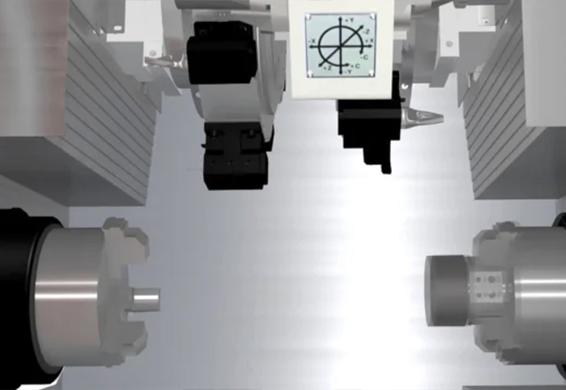

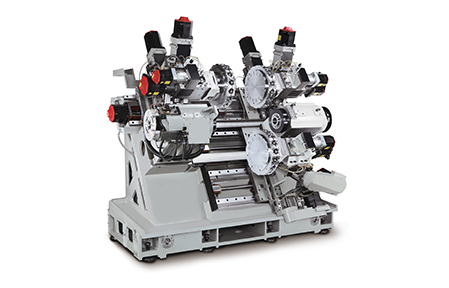

Quick Production by Innovative 3ʳᵈ Turret

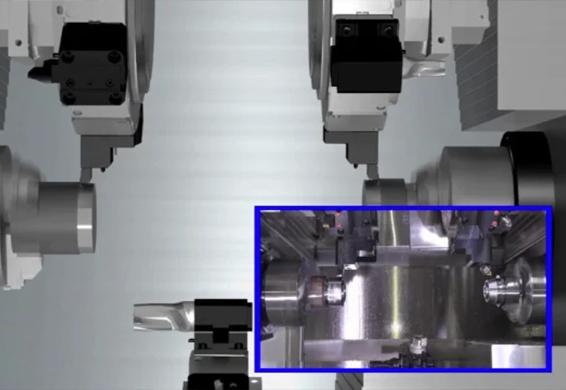

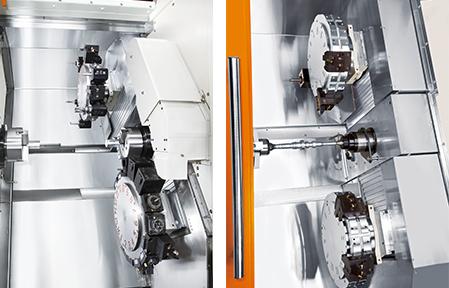

Minimizing the cutting time difference between OP-10 and OP-20 to balance cutting tempo and maximizing the turning length on twin-turret lathes when deep hole drilling is required.

Offering sufficient 32 tools for both OP-10 and OP-20 machining applications at quicker tool exchange compared as multi-tasking lathes with ATC.

Used as traveling steady rest, work rest or tailstock for more flexible applications.

Turning slender shafts or drilling/tapping the symmetric holes with upper turret simultaneously ("balanced cutting")

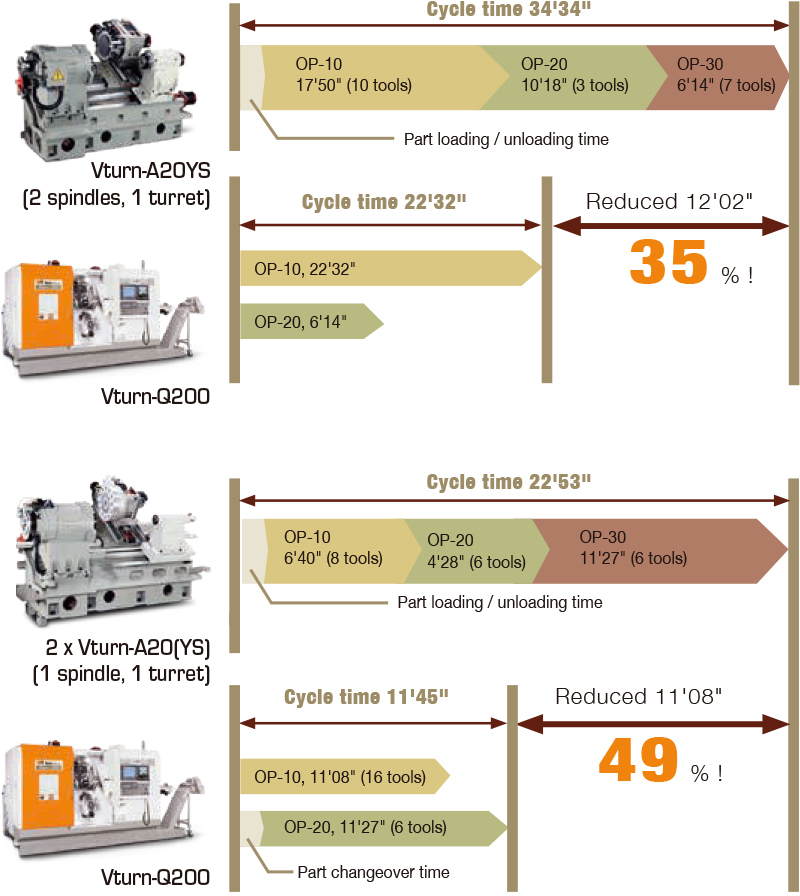

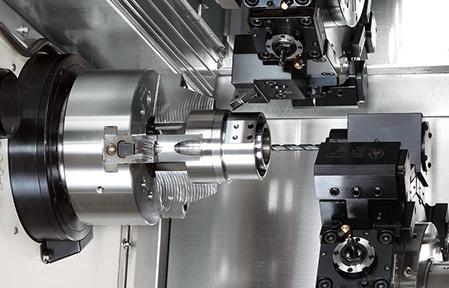

Machining Example

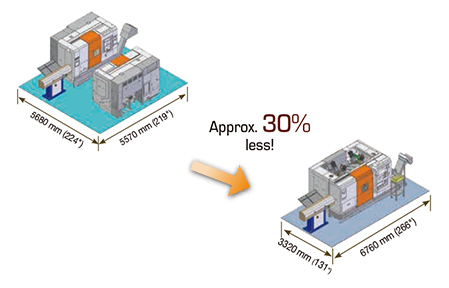

Quantitative Production with Less Floor Space

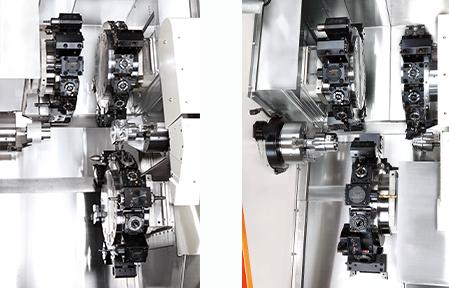

Quantitative Production by 3 Milling Turret with Y-axis!

- Y-axis (±45mm) on all 3 servo turrets.

- 48 tool stations with BMT-55 interface.

- High torque at low milling rpm.

- Twin built-in spindles.

Ergonomic design for easy & safe operation

Enclosed guarding with the high outlet chip conveyor fitted into the machine bed ensures no access to the machine during operation and no coolant leakages.

Front removed coolant tank with High pressure coolants by Grundfos pump SPK4-8 (or MTH4-40/4) improves the machining quality on part surface. Oil skimmer is installed on coolant tank to separate the oil layer from coolants.

Rotary control box with front mounted hydraulic gauges facilitate the easy adjustment and operation.

Spindle oil cooler for twin DDS spindles.

Powerful Hydraulic Chuck

Hydraulic 3-jaw hollow chuck is foot operated for easy and safe operation.

Victor's Lubrication Pump

High Quality lube pump (4 liters) ensures long service life for the machine.

Modular Design for Simpler Applications by 2 Turrets

- Vturn-Q200T2Y2 : with Double Turrets.

- Vturn-Q2-T2 : with MT-4 built in tailstock.

Manual Tool Presetter (Renishaw® Tool-Eye)

The Detachable Renishaw tool presetter allows more space within the machining area, and measures the tool lengths and diameters automatically.

Robotic Part Catcher for Unmanned Operation

By kinking the machine to either a bar feeder or work feeding system, a robotic parts catcher then collects the finished part removing it from the machine, for either manual collection or by a part receiver to from an unmanned machining line.

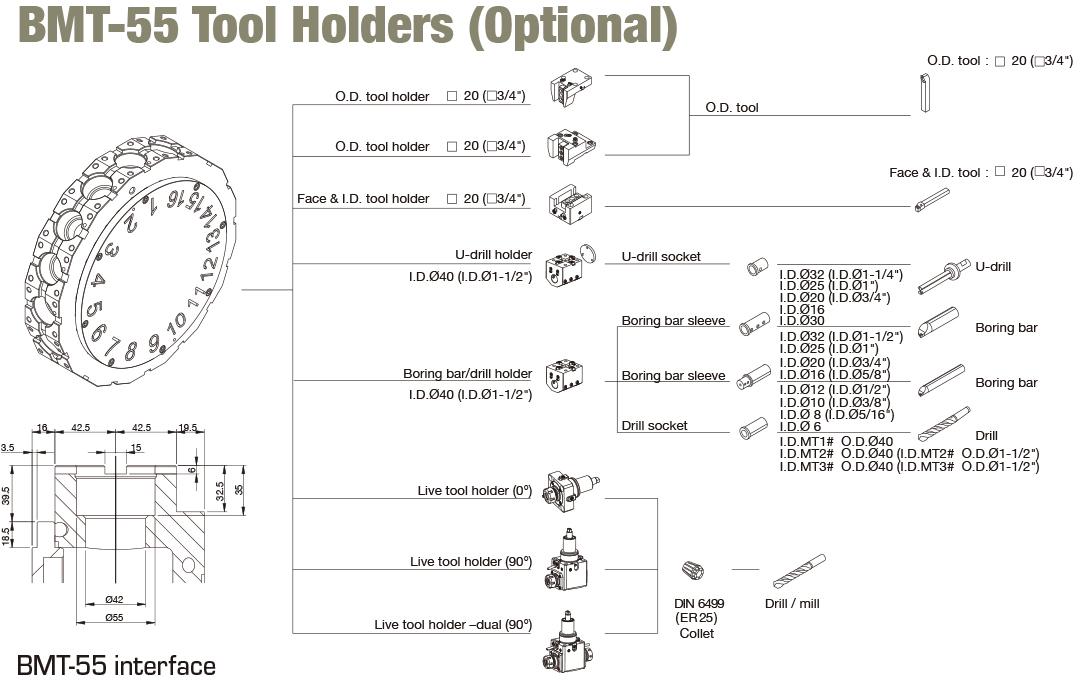

BMT-55 Tool Holder (Optional)

Accessories

Standard :

- Hydraulic chuck with soft jaws

- Chip conveyor

- Hand wheel (Remote MPG)

- Coolant flush on Z-axis cover

- 3 step warning light

- Oil skimmer

- Fanuc e-book (CD)

Optional :

- Kitagawa® power chuck

- Large spindle bore (LSB) 66mm (2.6") /4500rpm

- Manual tool presetter (Tool-eye)

- Robotic part catcher

- Part receiver for part catcher.

- Air conditioner for electrical cabinet (Panel cooler)

- Bar feeder interface

- Air blow

- Oil mist collector

- Hard jaws

- Car through

- Steady rest for lower turret

- BMT-55 tool holders

- Fanuc manuals