Features

Product Philosophy

(Fighting) Series has been developed to maximize the CP value (Cost/Performance) for end customer.

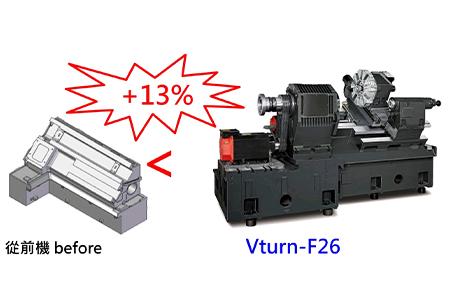

Concise Design with High-Rigidity

Inherit from the S(Strong) series high-rigidity design as the foundation.

Match the necessary functions for processing according to market demand, reducing the functions that are not commonly used in general processing.

Functional Equipment Upgrade

- Standard Turret coolant prevent chips from accumulating on the work space.

- Standard Coolant & tailstock rear flush to the bottom of Z-axis covers.

Improve User Friendly

New design 10.4 inch screen control panel, using an ergonomic controller will help your pain.

Optimize space hydraulic solenoid valves are installed on the front, which easy operability and improves efficiency.

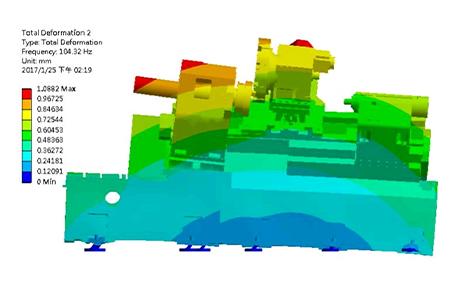

Rigidity Stable Accuracy

The weight of the new one piece slant bed is increased by 13%, which can avoid the vibration caused by the cutting force during cutting, and it is more powerful during heavy cutting.

Cutting Ability

The axis high-rigidity improved cutting ability, it can greatly improve the processing accuracy and meet the high precision requirements.

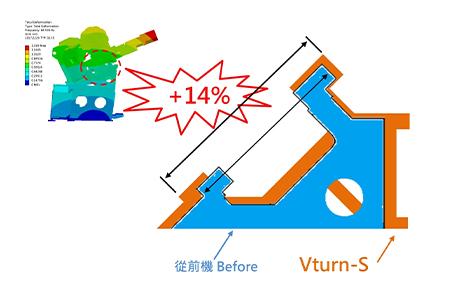

Rigidity Stable Accuracy

The boxway width is increased by 14%, which can improve the stability during axis feed.

High Productivity

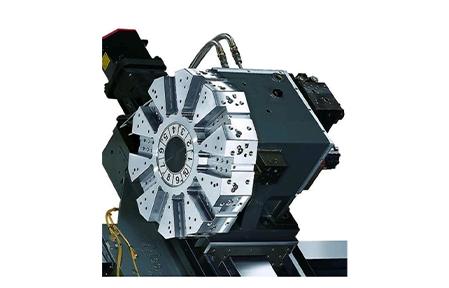

The Hydraulic driven turret indexing time 0.9 (T-T, opposite). Milling turret by BMT (bolt mounted tooling) for high static rigidity

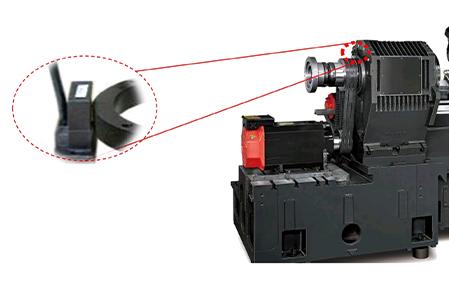

New Design Belt-Type Spindle

Heavy and light high-power spindle design: belt-type spindle, matched with high-power output spindle, is not inferior in general heavy cutting.

The weight of head unit is increased by 16% and shorter belt length -26%, and support NN bearing.

Standard process dynamic balance and low vibration.

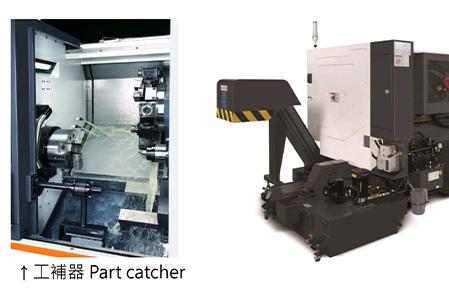

Accessories

Standard :

- 3-jaw Power chuck with soft jaws

- Programmable tailstock

- Chip conveyor with cart

- Automatic forced lubrication

- Fully enclosed splash guarding

- Tool holders

- 3 step warning light

- FANUC manuals by CD ROM

Optional :

- Manual tool presetter (Renishaw)

- Higher pressure coolants (3.3 bars/50Hz, 4.7 bars/60Hz)

- Air conditioner for electrical cabinet

- Part catcher

- Bar feeder interface

- Auto door

- Fanuc manuals

- Kitagawa chuck

- Hard jaws

- Tailstock center

- CE marked components