Features

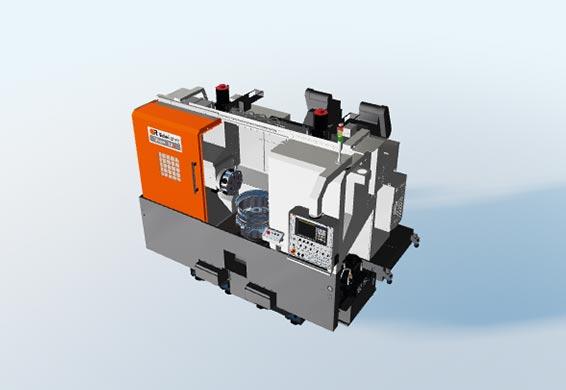

Vturn-18W/22W

Horizontal Lathes Vturn-18W/22W (T2)

Slant bed lathe has been specifically developed for max. efficiency in Alloy wheel processing. Horizontal type lathe minimizes chip build up in wheel to prevent swarf marring the surface during operation. The machine's ample capacity allows wheels of up to 22" on Vturn-22W (18" on Vturn-18W) to be processed. Specific features have been added to improve machine efficiency.

More Features Included

- High pressre coolants.

- Increased spindle power.

- Special 3 finger chuck and chip conveyor.

- No tailstock to reduce machine cost.

Rigid Structure for Accurate Wheel Turning!

- Meehanite cast iron structure with hardened box slideways quickly dampens cutting vibrations for high accuracy even under heavy cutting.

- Hydraulic driven turret with cast iron body easily handles continuous interrupted cutting common in wheel turning.

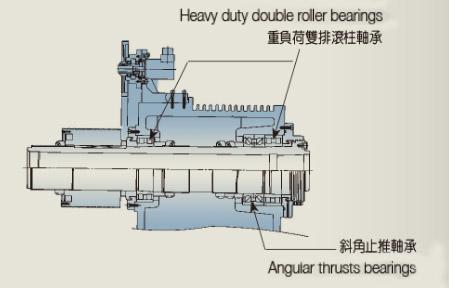

- Spindle supported by heavy duty roller bearings to maintain tight runout even under heavy cutting.

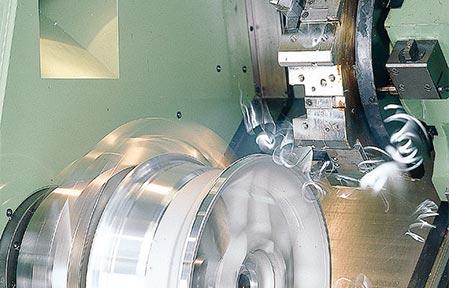

High Performance for Minimum Wheel Throughput Time!

- Low pitched ballscrews are used to increase axis thrust force while Fanuc α30i spindle motor is offered as standard.

- This combination of high thrust axis drives and powerful spindle facilitates high metal removal rates for optimum productivity.

- As low rpm's are rarely used in wheel turning, a direct belt drive is used to reduce inertia of drive system and improve acceleration times.

- Optional Built-in Spindle (DDS) with consistent dynamic balancing ensures fine finish on wheel surface.

Efficient chip evacuation

- High pressure coolant pump (6.5 bars) with 3 coolant pipes effectively washes chips away from the inside the wheel for coolant flow to prevent chip build-up within the wheel.

- Large coolant tank gives a coolant capacity of 360 liters (96 gallons) on Vturn-18W [400 liters (105 gallons) on Vturn-22W].

- Special chip conveyor removing long spiral chips that are formed in wheel machining is offered as standard.

Simple, Easy Wheel Loading for Maximum Operator Efficiency

- Automatic door opening & closing reduces operator workload particularly needed when continuously handling larger sized wheels.

- Special 3 finger hydraulic chuck clamped by standard foot switch is used to clamp the wheel rim, allowing simple yet accurate loading of wheels without fear of damage or distortion to the wheel.

Finger Chuck for OP-1 (Brake Side) or OP-2 (Road Side) Turning

For both size machines the 3 finger chuck is set-up for a single operation specified on ordering as standard. Suitable arms and fingers are offered as standard to allow complete range of wheel sizes. Range of sizes as follows:

- HC-1218 chuck with a clamping range of 12" to 18" wheels.

- HC-1520 chcuk with a clamping range of 15" to 20" wheels.

- HC-1522 chcuk with a clamping range of 15" to 22" wheels.

*Note:

- One size of spring loaded mandrel is offered as standard for OP-1 chuck.

- One size of mandrel with a complete set of spacers is offered as standard for OP-2 chuck.

- Changeover kit including mandrel and front plate to suit additional operation can be optionally ordered to allow both turning operations on the same chuck.

Finger Chucks for OP-3 (Diamond Cutting)

Diamond cutting on the front face turning is also popular for OP-2 for better finish on the wheel surface. ("OP-3" is only called by Victor Taichung for such a diamond cutting to avoid ambiguity). Besides the primary clamping on the outer rims using fingers, there exist a secondary clamping using the collet in the hub so the clamping quality is enhanced for better surface finish by diamond tools.

- Such type of finger chuck and built-in spindle are not recommended to be used compatibly with OP-1 chuck because the changeover is difficult and laborious.

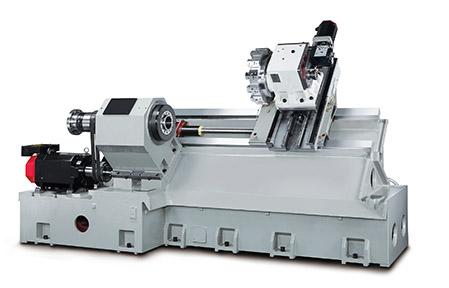

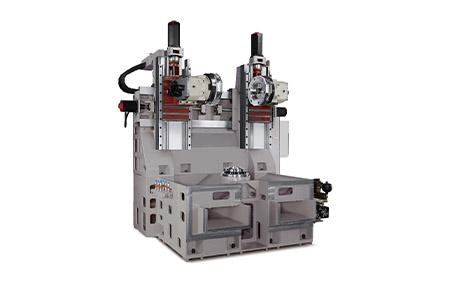

Vturn-V18W/V22W

Vertical Lathes Vturn-V22W/V26W (T4 & T2)

With the increasing demand for bigger Alloy wheel manufacturing, Victor Taichung has come up with an alternative solution for easier loading/unloading wheels and further reduces the spindle idle time.

Victor Taichung Vturn-V22W/V26W lathes are built from with new innovation to provide a 4 axis vertical CNC lathe specifically designed for Alloy wheel production.

Rigid Structure for Reliable Heavy-duty Turning!

- 2 piece Meehanite cast iron base with heavy ribbing base quickly dissipates localized vibration throughout cast structure. Hand scraping is used to ensure perfect mating with both case blocks.

- Rigid spindle is supported by large diameter bearings to maintain tight run-out even under heavy cutting, while vertical orientation removes accuracy problems encountered due to overhang.

- Robust turrets with cast iron bodies and hydraulic operated are designed to easily handle interrupted cuts encountered in wheel machining.

- Hydraulic tank is easily accessed and uses a heat exchanger to maintain low oil temperature and filtration system to ensure stable operation.

-

Deep Angled bed design with 2 large holes around the spindle collects high voulmn of chips and coolants to reduce the cleaning frenquency and according idle time.

High Powered Spindle Motor

- Fanuc high powered spindle motor 55kW (74HP) provides ample power to run heavy cuts with both turrets simultaneouly and compliments the high axis thrust force.

- Vturn-V22W-T2 with single turret and smaller motor 45kW (60HP) for OP-2 cutting.

Outstanding Features Stabilizes Cutting Process and Reduces Cycle Times

Twin VDI turrets (T4)

- Reduced cutting times by allowing 2 machining operations to be completed simultaneously.

- Orientating to tools to be directly opposed during machining ensures a more stable cutting process.

- VDI tooling allows quick tool changeover.

- Exclusive offset-tooling design further enables the I.D. turning by two turrets moving simultaneously to double the cutting efficiency for the first operation OP-1.

Outstanding Features Stabilizes Cutting Process and Reduces Cycle Times

OP-10 or OP-20 turning

- Fully hydraulic 3-finger chuck with stiff arm and pull-back clamping guarantees cutting stiffness, better surface finish and longer service life.

- Exclusive design for one single chuck with multiple arm-and-finger packages provides a cost-effective and high flexibility solution for the customers.

- No need to change the complete chuck for different size of wheel turning.

- Vturn-V22W with HC-V1320 or HC-V1522 chuck for 13"-18" or 15"-22" wheel tuming.

- Vturn-V26W with HC-V1726 chuck for 17"-26" wheel turning.

Extra High Efficient Chip Evacuation & Removal

- TWO chip conveyors (T4) with king size coolant tank 950/1550 liters (250/408 gallons) for Vturn-V22W/ V26W disposes high volume of chips and enhances the production without scratching on the wheel surface because of less chip build-up and high flow rate coolant pump Grundfos CM10-2.

- Oil skimmer effectively removes fine metal particles from the coolant to ensure stable coolant flow.

Accessories

Vturn-18W/22W

Standard :

- Oil skimmer

- 3 step warning light

- Japanese ballscrews

- Water & air gun interface

- Fully enclosed guard

- Tool box & hand tools

- Leveling blocks

- Tooling accessories

- Auto door

- High pressure coolant - Grundfos SPK 4-15 (or MTH4-50/5)

- Coolant nozzle

- Special chip conveyor

- Automatic lubrication

- Air conditioner for electrical cabinet

Optional :

- Homtech 3 jaw finger chuck (specify OP.1 or OP.2)

- Window on door

- Built-in spindle for OP3 diamond turning

- VDI turret - no extra charge, but no tool holders provided

- Higher power spindle 37/45 kW (50/60 HP)

- Air blow system

- Oil mist remover

Vturn-V18W/V22W

Standard :

- Fully enclosed guarding

- Finger chuck

- VDI tool holders including exclusive OFFSET tooling

- Auto door

- High pressure and high volume coolant (2 Grundfos pumps CM10-2)

- 2 Chip conveyors

- Remote MPG

- Oil mist remover

- Tool box

- Levelling blocks

- Air conditioner for electrical cabinet

- 3 step warning light

- Air blow system

- Stepper for operator

Optional :

- No chucks

- Wheel lifting device

- Interface for robot